- OBJECTIVE:

- To lay down a procedure for operation of Refractometer, Make – Rudolph Research.

- SCOPE:

This SOP is applicable to the procedure for operation of Refractometer, Make – Rudolph Research at {Company Name} {Location}.

- RESPONSIBILITY:

- Officer/Executive/Designee Quality Control – Shall be responsible for operation as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- Check the cleanliness of the work area and instrument.

- Connect the power cord to the electrical supply source.

- Switch on the instrument by using the ON/OFF switch present on the backside of the instrument.

- Lift the presser and clean the sample well by using solvents like water, ethanol, acetone, Iso propyl alcohol.

- Place the sample to be measured in the sample well, after placing the sample in the sample well, close the presser.

- Place enough sample so that it touches the inner part of the silver metal ring all the way round.

- Now press the Temp soft key present on the touch screen, two options are displayed

- Temp Control

- Temp Correct

- Now press the Temp control soft key and enter the required temperature.

- Press the Measure key, system prompts for operator password enter the password and press enter.

- Now press continue the stabilizing temperature message displays.

- Press Enter manual and enter the Lot ID and press enter.

- Press Enter manual and enter the sample ID and press enter.

- The sample Refractive index measurement takes place.

- Once the scan is complete the results are displayed.

- Now press Yes key if results are accepted, No key if results are not accepted.

- Now the system prompts for Review electronic signature enter the password, press continue and enter the comment and press enter.

- Accept this comment message displays, press Yes if comment is accepted, No if comment is not accepted.If No is pressed then enter the new comment and press enter, accept this comment message displays, press enter.21CFR11 back up in process message is displayed and the data backup is completed automatically.

- Now press the Print/Send key and the report is printed.

- Once the analysis is completed wipe off the sample with paper towel, clean the sample well using water or suitable solvent depending upon the nature of sample.

- Enter the details of usage in the logbook.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-refractometer-make-rudolph-research/

- REFERENCES:

Not Applicable

- ANNEXURES:

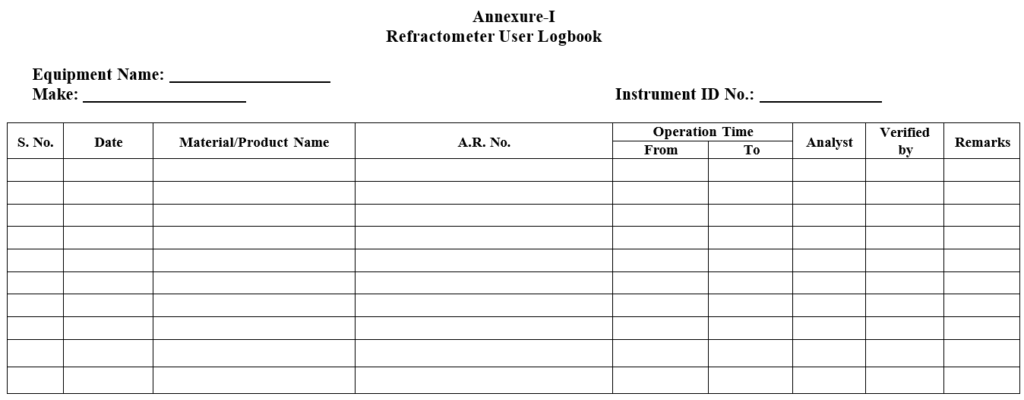

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Refractometer User Logbook |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| NMT | : | Not More Than |

| QC | : | Quality Control |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

Refractometer User Logbook

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-refractometer-make-rudolph-research/