- PROCEDURE:

- Instrument Name: SHIMADZU HPLC

- MODEL LC-2010CHT

- PROCEDURE FOR GENERAL CLEANING:

- Check that the power supply to the instrument is switched ‘OFF’ before cleaning.

- Clean the instrument with a clean dry cloth every day and occasionally wet cloth dipped in dilute soap solution may be used.

- Precaution to be taken to clean the instrument immediately with dry cloth to remove the moisture.

- Note: The HPLC should be calibrated and calibration details shall be verified in the HPLC user logbook as well as on calibration status Label, which is fixed on front of the instrument before operating the HPLC.

- PREPARATION OF MOBILE PHASE:

- Always use filtered (through 0.45 or 0.20 micron membrane filter) mobile phase/solvents.

- PROCEDURE FOR OPERATION OF LC-2010CHT INSTRUMENT:

- Switch on the LC2010C instrument by pressing the on/off switch located at the front side of the module.

- Initialization takes place and it will ask for the password.

- Enter the password and Press F2 button to confirm.

- The main window will appear. Click on ‘Met’ to go to Method menu.

- Keep all A, B, C, D channel tubing’s as well as rinsing tubing’s into methanol or required solvent.

- To purge the channels click on purge and give the required time for all channels.

- You can change the flow rate, wavelength, Oven Temperature, composition of A, B, C and D etc. by pressing Upward and downward keys.

- Change the Seal wash solution on daily basis with Milli- Q Water and Acetonitrile / Methanol (50:50).

- PROCEDURE TO OPERATE LC -2010CHT BY EMPOWER:

- To Create New Instrument Method And Method Set

- Power up the system instrumentation in the following order.

- Switch on the LC-2010C instrument by pressing the on/off switch located at the front side of the module.

- Switch on the computer, The Windows desktop appears once the computer is powered up asking to log-on to the operating system.

- Press “Alt + Ctrl +Delete” buttons simultaneously. Windows XP logon screen appears.

- Enter the Username and Password to log on to System.

- Click on “EMPOWER Login…” Button. Empower login windows appear. Enter the allotted Username of the individual, password of the individual, and select the database as “WAT7” from the dropdown list and click on OK to log on to the Empower.

- Double click the “Browse project” button. “Browse project” window is displayed. Click to select required project then project window appears.

- Go to “Tools” on menu bar on the top and select Quick set or press the Quick set button on the tool bar.

- “Select System” window is displayed. Select required system and click OK.

- Quick set will start initializing. Quick set window is displayed.

- Select the required instrument method, from the “Instrument Method” window at the bottom.

- Click “Edit” to open the Instrument method.” Instrument Method” edit window is displayed.

- Select Pump button and select following parameters Mode (Isocratic or Low Pressure Gradient) Set total flow in ml and 100 % of any one channel by selecting the required channel marked or In case of Low Pressure Gradient select percentage of flow from multiple channels. Pressure limit (P.Max and P.Min).

- Select Detector A and select following parameters Lamp- D2 , Wavelength in Ch1.

- In case of dual wavelength – go to system configuration, select detector configure and select dual mode “ON”

- Select Auto sampler and select the following parameters sample Rack –Rack 1.5ml 70 vials , Rinsing volume -200µl, Needle stroke-52mm, Sample Suction Speed 15µl/sec, Rinse mode (Before aspiration or After aspiration or Before and After aspiration), Cooler Temperature marked and enter the required temperature.

- Select Column Oven button and select Column Oven Temperature by marked and enter the required temperature

- Select Controller button and select Degasser marked

- Go to ‘File’ menu select save Instrument method as and give the title of the instrument method and save it. Go to file menu and select Exit file.

- Go to the system screen and click on Develop methods, select the Instrument method created and click next and click finish.

- The new instrument method and method set is created.

- Procedure to Run Single Inject Mode or Run Samples in Sequence:

- To perform single injection; click on “Single” on the Quick set window.

- Enter the information like Vial No., Sample name, Function, Method set, Injection volume and Runtime in the sample-loading table.

- Open the door of the Auto sampler and keep the vial to be injected in the Auto sampler (sample loading tray) Close the door.

- Go to “Inject” on the main menu bar on the top and select “Make injection” or press the “Inject” button below the Sample table; to start the injection.

- For performing injections of more than one sample, select “Samples” on the Quick Set Window.

- Fill the “Sample table” by “Auto Fill” mode.

- Select the “Sample Name” field in the Sample table and click on the right button of the mouse. Select “Auto Fill” from the menu.

- Enter the information like “Sample Name”, “Incrementing prefix” and “Incrementing suffix”, “Vials numbers to be injected” and click OK.

- Similarly Auto fill is done for “Method set”, “# of inj”, “inj.vol”, “Run time” fields by following the above procedure.

- The Sample table is filled with the above information.

- Go to “File” on main menu bar on the top and select “Save sample set method as” and give the sample set number For Example 001,002,003……. where 001 is the first sample set number in that month, 002 is the second sample set number in that month and so on.

- “Sample set method” window is displayed. Enter the sample set name and press OK to save

- Open the door of the auto sampler and keep the vials in the auto sampler (sample loading tray) according to the queue in the sample-loading table and close the door.

- Go to main menu bar and select one of the following modes “Run only” mode for data acquisition only.

- Select “Run and process” for acquisition and processing. Select this mode only when processing method is created earlier.

- Select “Run and report” for acquisition, processing and reporting. Select this mode only when processing and reporting methods are created and are included in the method set.

- Go to “Inject” on the main menu bar on the top and select “Run Sample set” or press the “Run” button (Green button) on the tools bar.

- “Run Sample Set” window is displayed. Press “Run” to start the sample set.

- The sample in the first row will be highlighted with red colour and the injections get started.

- After completion of the injections, click opens the project window.

- Click channel button in the views on the project screen. All the Channels are displayed. Alternatively select “All channels by date” filter to view all Channels.

- Select a completed injection in the channel view table.

- Go to “Tools” on the main menu bar on the top and select “Review”. Or click Start-review button in the tools. Review data: Project window appears.

- Review window is displayed with the chromatogram.

- Go to “Window” on the menu bar on the top and select “Processing method”.

- Enter the parameters Peak width, Minimum area, Minimum height, and Threshold value in the respective boxes of Integration table. Program the events if necessary.

- Click “Components” button. Enter “Component name”, “Retention time”, “and RT window”.

- Click on “Suitability” button and select Calculate suitability results.

- Enter “Void volume” and select the required pharmacopoeia or “All” to calculate System suitability as per all pharmacopoeia.

- Close the “Processing Window”.

- Go to “Process” on the main menu bar and select “Integrate” and then Quantitate”. Or press “Integrate” button and then “Quantitative” button on the tools bar.

- Now zoom the chromatogram to check for proper integration of peaks. If the integration is not proper alter the above parameters in the integration event table.

- Go to “File” and select “Save method as”.

- Enter the file name and click “SAVE”

- Click File and ‘Save Result’. Then file ‘Exit’.

- Click the Display results button in View of the project window.

- Select the above saved result of the sample in the Result view table.

- Click Preview button in the tools and select the required report or select report method from the Preview: Report Method Selection.

- The instrument starts creating the report and is displayed on the screen.

- Double click on chromatogram to modify the chromatogram scaling.

- Select User defined in scaling type. Feed required scale parameters, like X-start, Y-start, X-end, Y-end. Double click the Peak result table below the Auto scaled chromatogram to modify the table format by selecting the required parameters.

- Select the required peak results by double clicking the parameters like: Component name, retention time, area, area %, height, height % in the peak fields, Channel name, Date acquired, Injection from the Sample fields System suitability parameters like USP Tangent, USP Tailing, and Resolution from system suitability fields.

- Click file and save

- Click Printer button to print the current report.

- Click File exit.

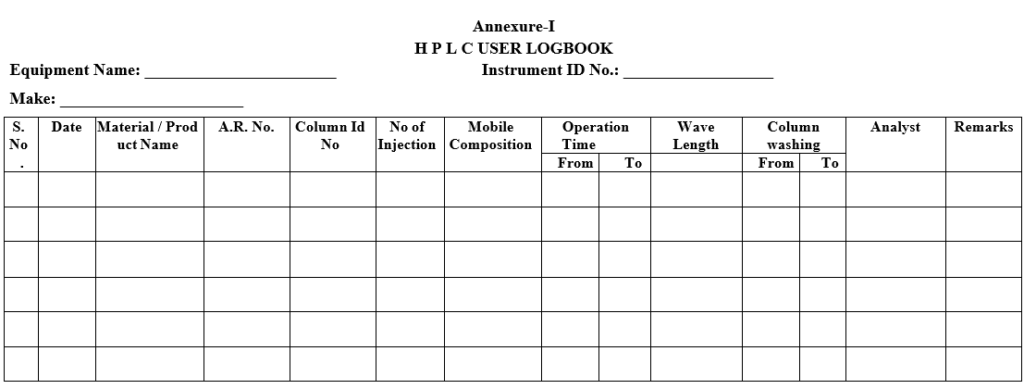

- Enter the details in HPLC User Logbook as per Format-I.

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | HPLC User Log Book |

- ABBREVIATIONS:

| No. | : | Number |

| mm | : | millimeter |

| RT | : | Retention Time |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

Annexure-I

HPLC USER LOGBOOK