- PROCEDURE:

- Operation Procedure:

- Check and ensure the compressed air pressure in between this limit 3.0-3.5Kg/cm2.

- While removing the filter from user point close the valve and then remove. Check and ensure the differential across the cartridge filters should be NMT 250mm of WC.

- Switch ‘ON’ the main power supply.

- Switch ‘ON’ machine, and then machine will start automatically.

- Numbering procedure of HEPA filter:

- A unique number consisting of 11 alphanumerical characters shall be allotted by Engineering.

- For example, first facility layout is numbered as XXX/DX/HF/001/F01.

- XXX : represents company name abbreviations

- ‘DX’ represents dust extraction unit.

- HF represents HEPA filter.

- 001: stands for equipment numbers starting from 001.

- F01: stand for filter number.

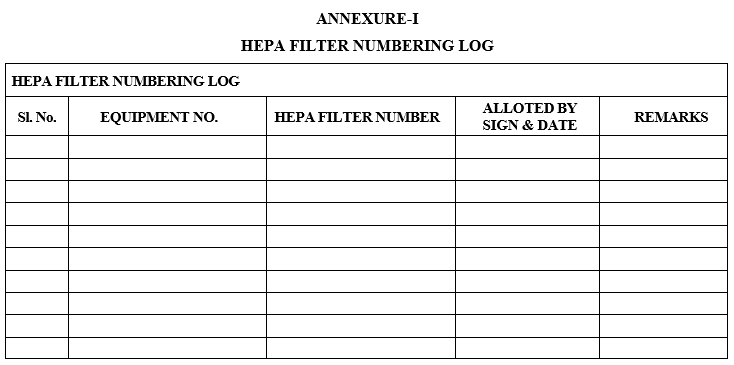

- The allotted numbers shall be entered serially in HEPA filter numbering log (Annexure-I)

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | HEPA filter Numbering Log |

- ENCLOSURES:

- SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Engineering

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| HEPA | : | High Efficiency Particulate |

| NMT | : | Not More Than |

| DP | : | Differential Pressure |

| SOP | : | Standard Operating Procedure |

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be Written manual |

Annexure-I

HEPA FILTER NUMBERING LOG