- OBJECTIVE:

To lay down a procedure for Passivation of Storage & Distribution purified water system.

- SCOPE:

This SOP is applicable for Passivation of Storage & Distribution purified water system at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering shall be responsible for Passivation of Purified water system.

- HOD/Executive – Engineering shall be responsible to ensure the compliance with respect to Purified water system.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Passivation, refers to the process of coating a material to make it “passive,” meaning less susceptible to corrosion or chemical attack. This is typically achieved by forming a protective oxide layer on the surface of the material.

How it works:

- Passivation often involves a chemical reaction between the material and its environment (usually an acidic or oxidizing solution).

- This reaction leads to the formation of a thin, dense oxide layer on the surface.

- The oxide layer acts as a barrier, hindering further reactions between the underlying material and the environment, thereby protecting it from corrosion.

- Passivation shall be carried out when any modification or expansion work has done in purified water storage tank & circulation loop.

- Passivation shall be carried out with 5% w/w of Nitric acid (HNO3) solution & 1% w/w of Sodium Hydroxide (NaOH) solution.

- Purified water storage & circulation loop shall be passivation as per the following procedure:

- Initial Water rinse:Take a high level of water in the purified water tank.

- Ensure the purified water pump suction valve and delivery valve of pump is open.

- Start the purified water pump.Rinse for 5 minutes on surfaces of tank or parts.

- Drain the water from the return loop until the water level is low in the tank.Stop the purified water pump.

- Drain the tank from the tank drain valve.

- Acid wash:Take 750 liters of purified water in purified water storage tank.

- Prepare Nitric acid solution by adding 37.5 liters of nitric acid solution having70% concentration with 750 liters purified water in purified water tank.

- Wear safety overalls gloves, face-eye-masks before preparing solution.

- Start the purified water pump.Circulate the Nitric acid solution for 60 minutes through the loops and tank.

- Stop the purified water pump.Drain the solution completely from the drain valves for Purified water tank and loops respectively.

- Close the valves purified water tank drain & loop drain.

- Final water rinse for Nitric Acid Collect the Purified water in the Purified water storage tank until reaches to high level.

- Start the purified water pump.

- Rinse surfaces with purified water for 30 minutes.

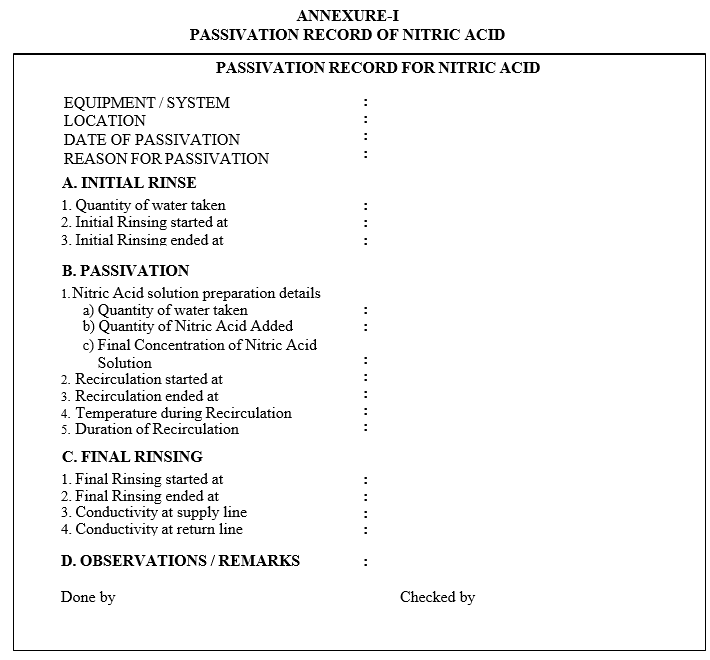

- Repeat the above cycle of (Above 3 steps) for one more time with Purified water.Drain and sample till free from Iron residues pH and Conductivity of supply and return loops are within tolerances.Record the Passivation of Nitric acid details as per Annexure-I Alkaline Wash:

- Take 750 L of purified water in a purified water storage tank.

- Prepare alkaline solution by adding 7.5 liters of alkaline solution (1% w/w concentration) with 750 litres purified water in purified water tank.

- Wear safety overalls gloves, face-eye-masks before prepare solution.

- Start the purified water pump.

- Circulate the Alkaline solution for 60 minutes through the loops and tank.

- Stop the purified water pump.

- Drain the solution completely from the drain valves for Purified water tank and loops respectively.

- Close the valves purified water tank drain & loop drain.

- Collect the Purified water in the Purified water storage tank.

- Final water rinse for Alkaline Solution

- Collect the Purified water in the Purified water storage tank until reaches to high level.

- Start the purified water pump.

- Rinse surfaces with purified water for 30 minutes.

- Repeat the above cycle of (Above 3 steps) for one more time with Purified water.Drain and sample till free from Iron residues pH and Conductivity of supply and return loops are within tolerances.

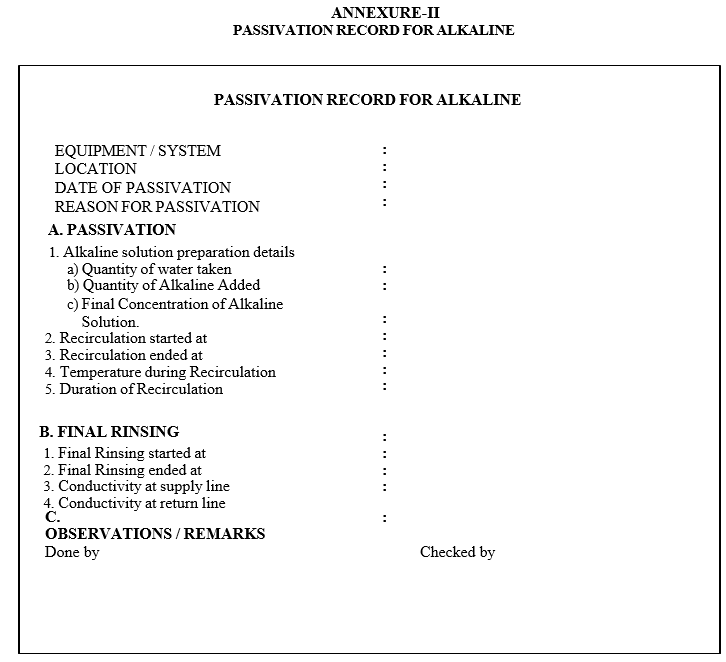

- Record the Passivation of Alkaline solution details as per Annexure-II.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Passivation Record for Nitric Acid |

| Annexure-II | Passivation Record for Alkaline |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

L : Liter

V : Valve

P : Pump

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

PASSIVATION RECORD OF NITRIC ACID

ANNEXURE-II

PASSIVATION RECORD FOR ALKALINE