About Sejong 77 station Model HRC 77S AWC:

Test: Measuring the noise level emitted by the machine.

The Sejong 77 station Model HRC 77S AWC machine is a high-speed, double-sided tablet press designed for mass production in the pharmaceutical industry. It is capable of producing up to 646,000 single-layer tablets per hour and 184,000 double-layer tablets per hour

The machine features a large 15-inch touch screen for easy operation and monitoring, as well as an Automatic Weight Control (AWC) system for accurate tablet weight control. It also has a disk change system that maximizes productivity and a double-side discharge system for efficient tablet collection.

The HRC 77S is a reliable and efficient tablet press that is ideal for high-volume production of pharmaceutical tablets. It is available in a variety of configurations to meet the specific needs of different customers.

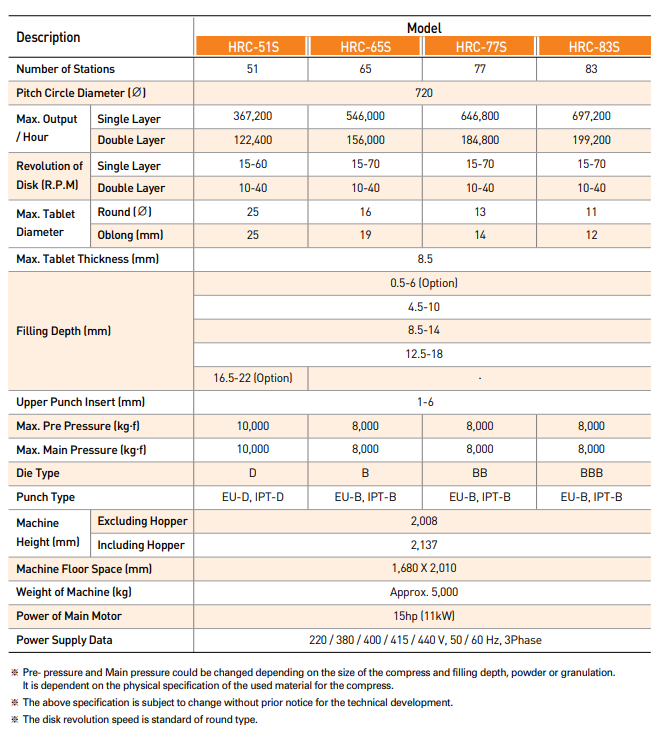

Specification of HRC-S Series

Specification taken from: www.keyinternational.com

Performance Qualification (PQ) is a critical step in ensuring the consistent performance of Sejong 77 Station Model HRC 77S AWC machine. It involves a series of tests to verify that the machine operates within specified parameters and produces tablets that meet predefined quality standards.

Key Parameters for the Sejong 77S AWC Machine for PQ:

Tablet Weight Uniformity:

Test: Weighing a sample of tablets and calculating the weight variation.

Parameter: Percentage of tablets within specified weight limits.

Tablet Hardness:

Test: Measuring the force required to break a tablet.

Parameter: Minimum and maximum hardness limits.

Tablet Thickness:

Test: Measuring the thickness of a sample of tablets.

Parameter: Specified thickness range.

Tablet Friability:

Test: Subjecting tablets to abrasion and measuring weight loss.

Parameter: Maximum allowable weight loss.

Tablet Disintegration Time:

Test: Immersing tablets in a dissolution medium and measuring the time taken for them to disintegrate.

Parameter: Maximum disintegration time.

Machine Efficiency:

Test: Calculating the percentage of time the machine is producing tablets.

Parameter: Minimum efficiency.

Machine Noise Level:

Parameter: Maximum allowable noise level.

Performance Qualification Protocol

Find below pages for completes Performance Qualification protocol:

Key Parameter of Below Page

Its a page of Pharmaguidhub

Find below pages for complete protocol:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/performance-qualification-protocol-for-sejong-77-station-double-rotary-compression-machine/

Our Knowledge Sharing Platform:

To get regular updates on pharmaceutical industry you can join us at our following knowledge sharing platforms:

- Web address: www.pharmaguidehub.com

- Telegram Link: https://t.me/pharmaguidehub

- LinkedIn: www.linkedin.com/in/pharmaguidehub

- Facebook Page Link: https://www.facebook.com/profile.php?id=61557224322551

- Twitter Link: https://x.com/pharmaguidehub

- WhatsApp Group Link: https://chat.whatsapp.com/HY09XT4iEL07oCE4Am3JUW

Key Parameter of Below Page

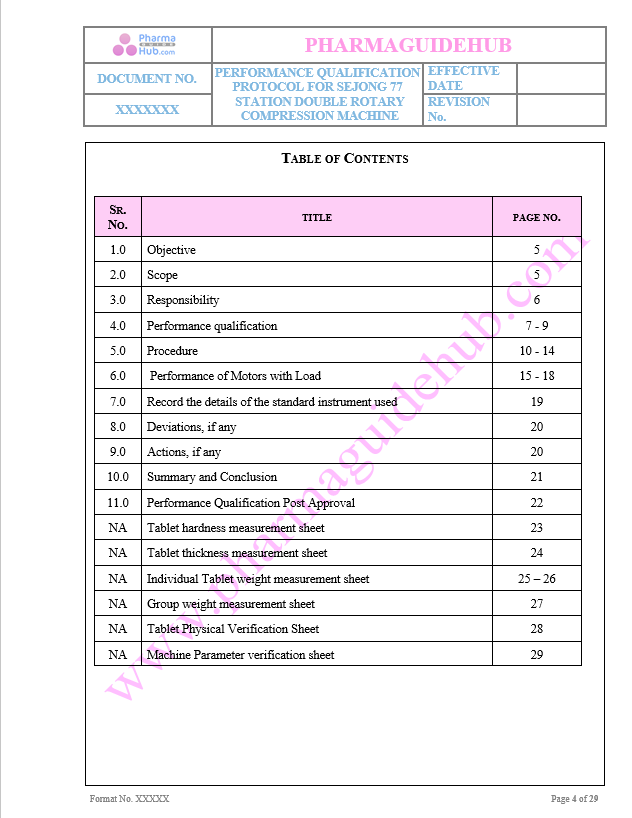

Table of Contents:

Find below pages for complete protocol:

Key Parameter of Below Page

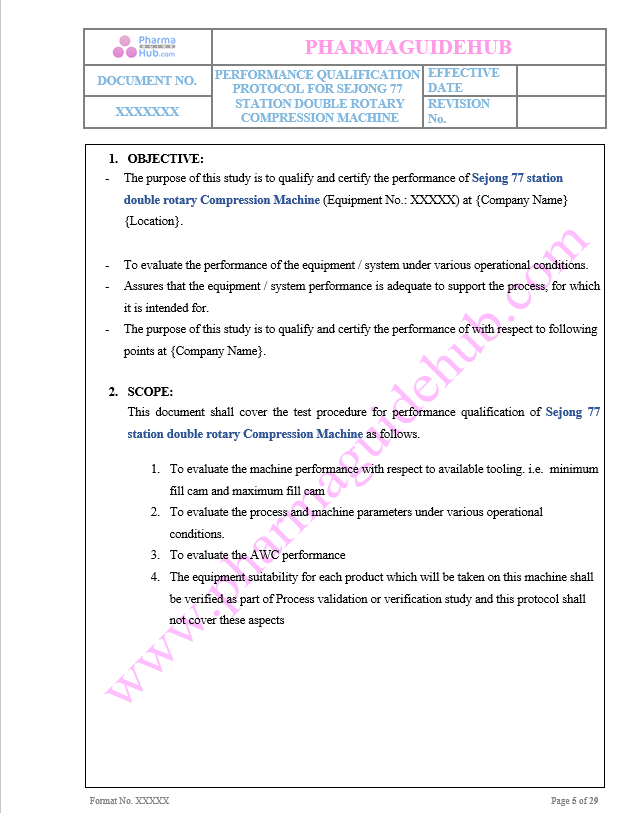

Objective

Scope

Find below pages for complete protocol:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/performance-qualification-protocol-for-sejong-77-station-double-rotary-compression-machine/

Key Parameter of Below Page

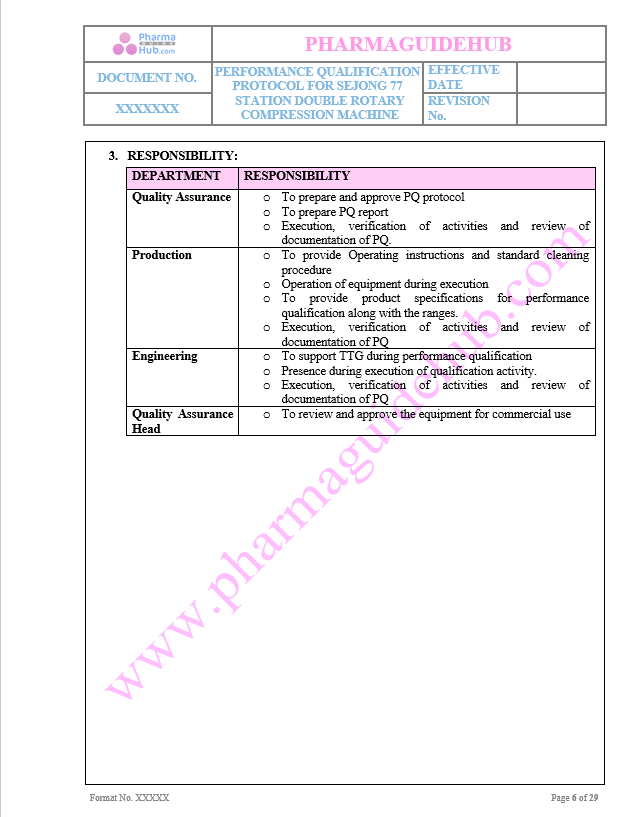

Responsibility:

Find below pages for complete protocol:

Key Parameter of Below Page

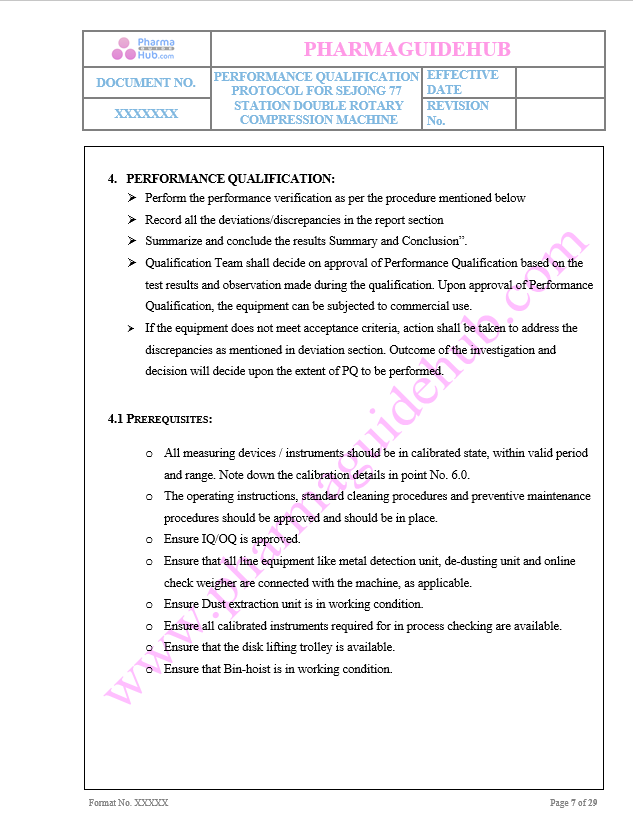

Perforformance Qualification:

Prerequisites

completeFind below pages for completes protocol:

Key Parameter of Below Page

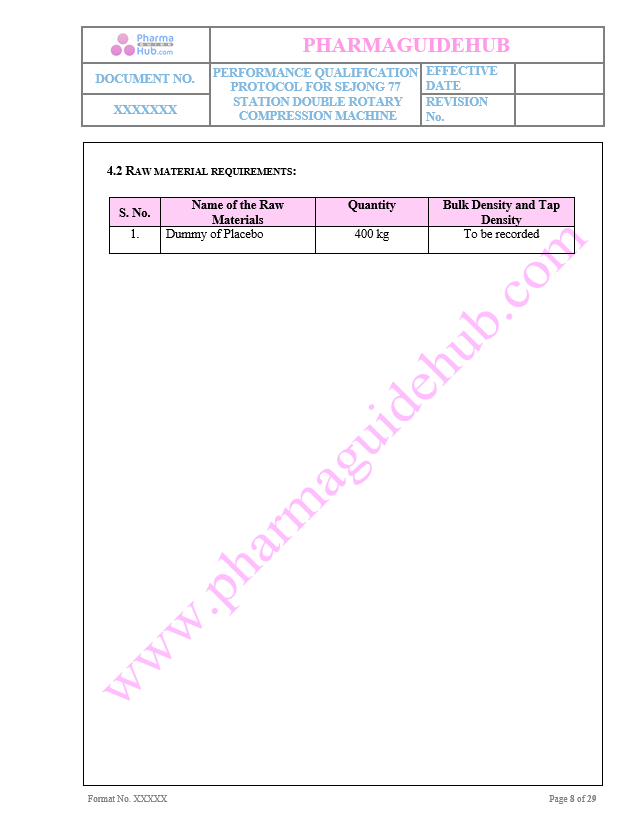

Raw material requirement:

For the execution of PQ required material details are given below

Find below pages for complete protocol:

Key Parameter of Below Page

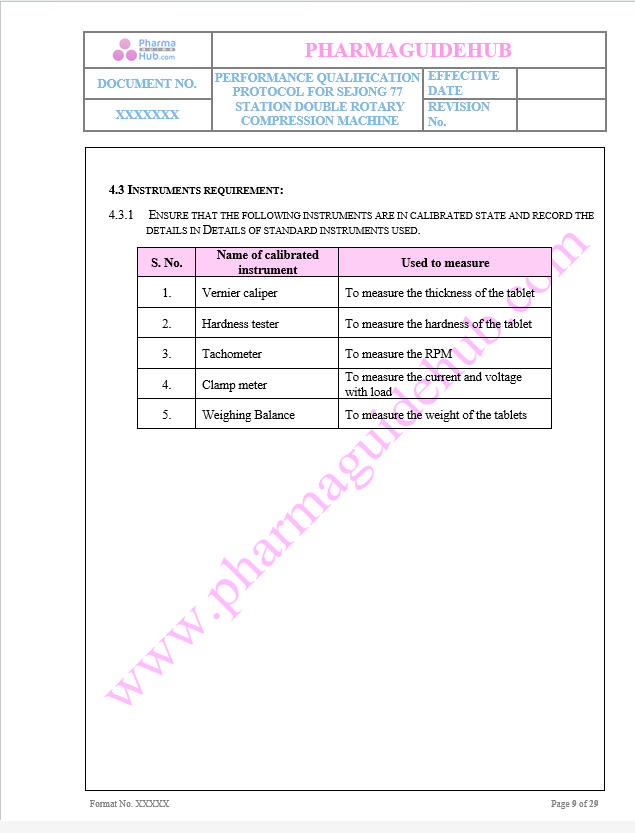

Required Instrument:

For the execution of PQ Required instrument details is given below

Find below pages for complete protocol:

Key Parameter of Below Page

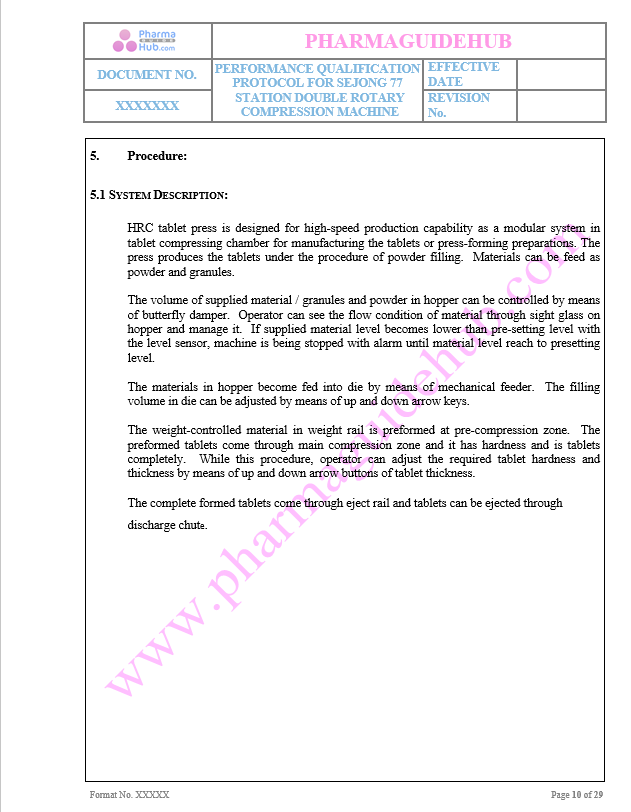

Procedure:

For the execution of PQ required system description is mentioned below

Find below pages for complete protocol:

Key Parameter of Below Page

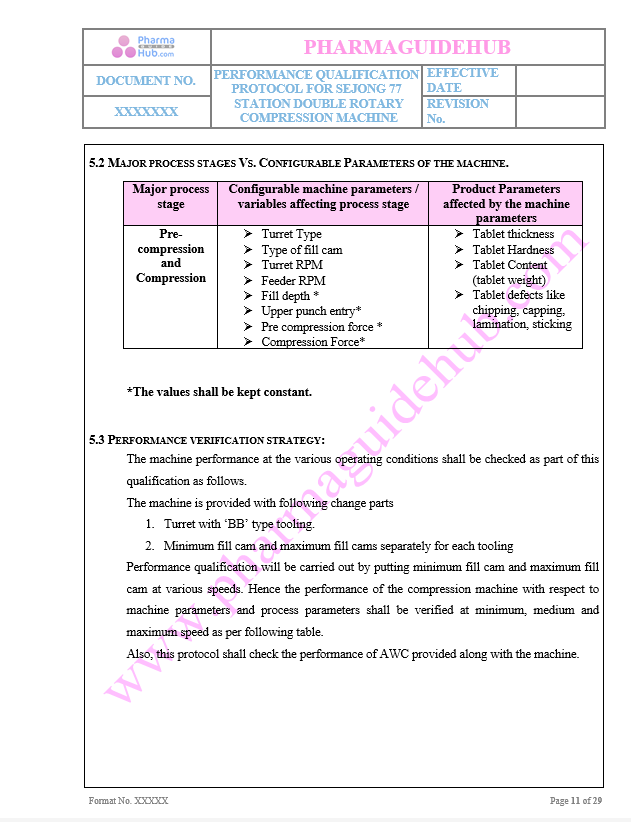

Major Process stages and configurable parameters detail has given below

Performance verification stratergy given below

Find below pages for complete protocol:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/performance-qualification-protocol-for-sejong-77-station-double-rotary-compression-machine/

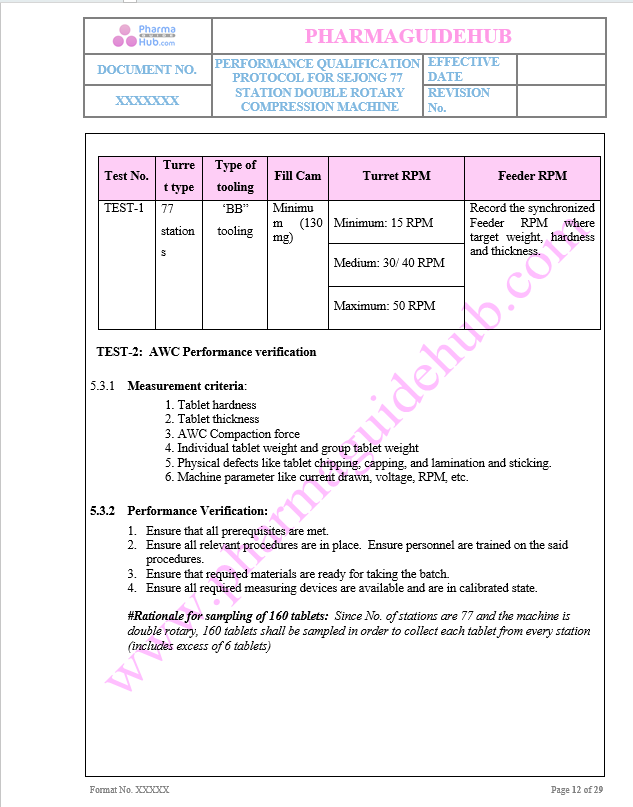

Key Parameter of Below Page

Measurement criteria

Performance verification criteria

Find below pages for complete protocol:

Key Parameter of Below Page

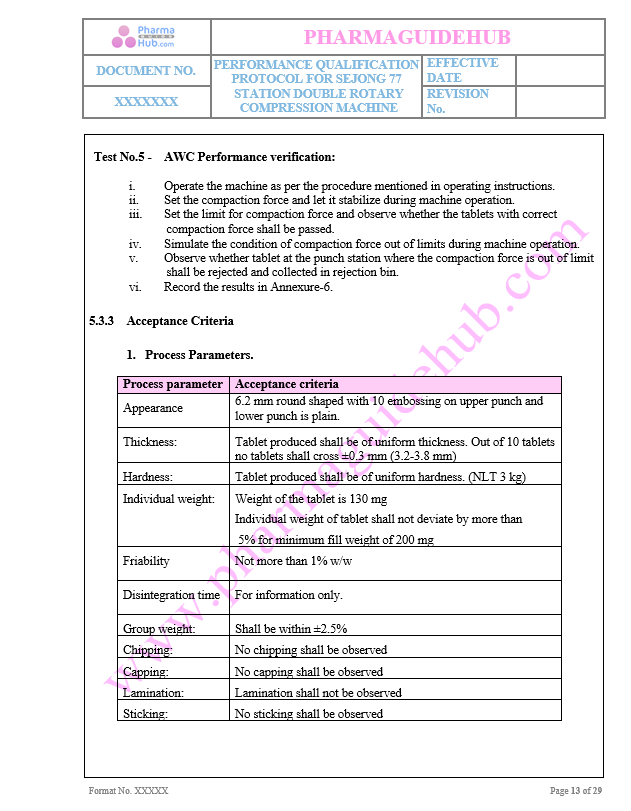

AWC Performance Verification

Acceptance Criteria

Process Parameter

Find below pages for complete protocol:

Key Parameter of Below Page

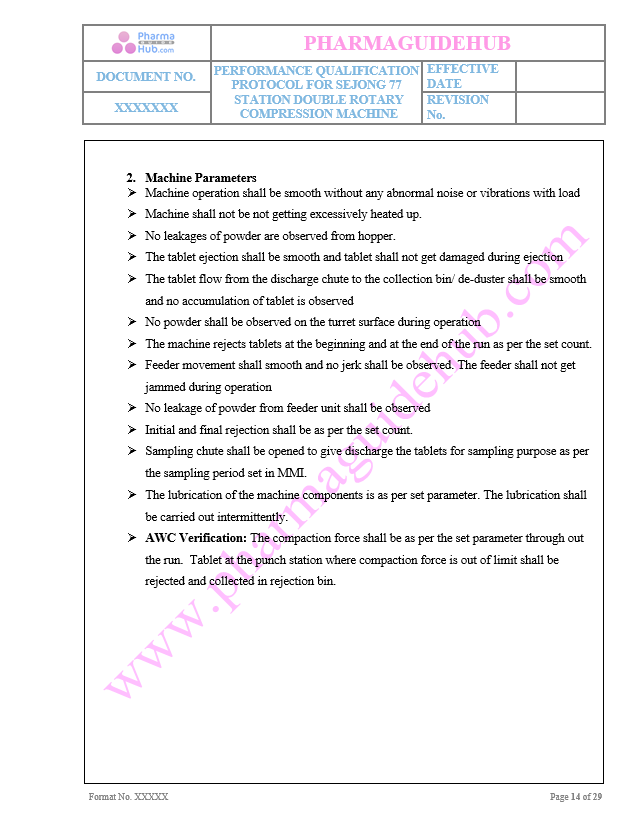

Machine Parameter

Find below pages for complete protocol:

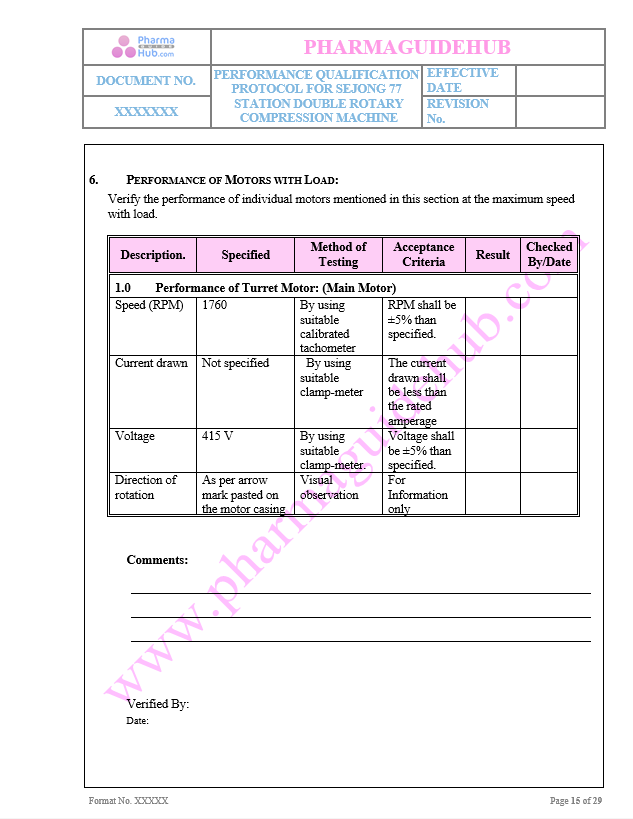

Key Parameters of Motors

Performance of Turret Motor

Find below pages for complete protocol:

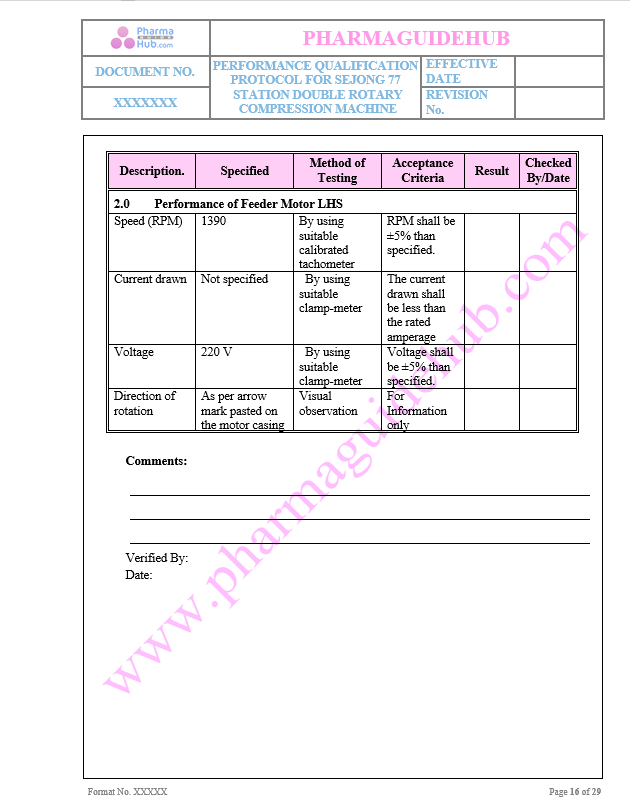

Key Parameters of Motors

Performance of Feeder Motor LHS

Find below pages for complete protocol:

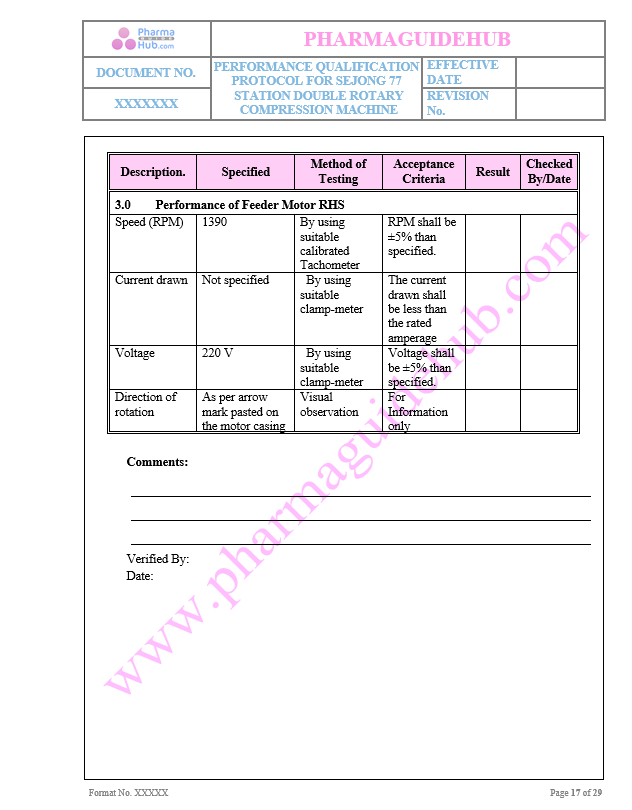

Key Parameters of Motors

Performance of Feeder Motor RHS

Find below pages for complete protocol:

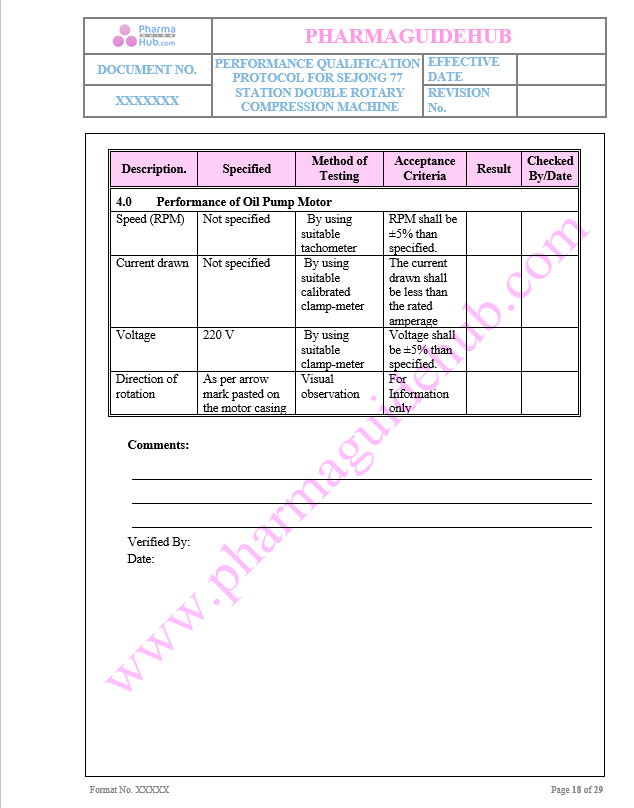

Key Parameters of Motors

Performance of Oil Pump Motor

Find below pages for complete protocol:

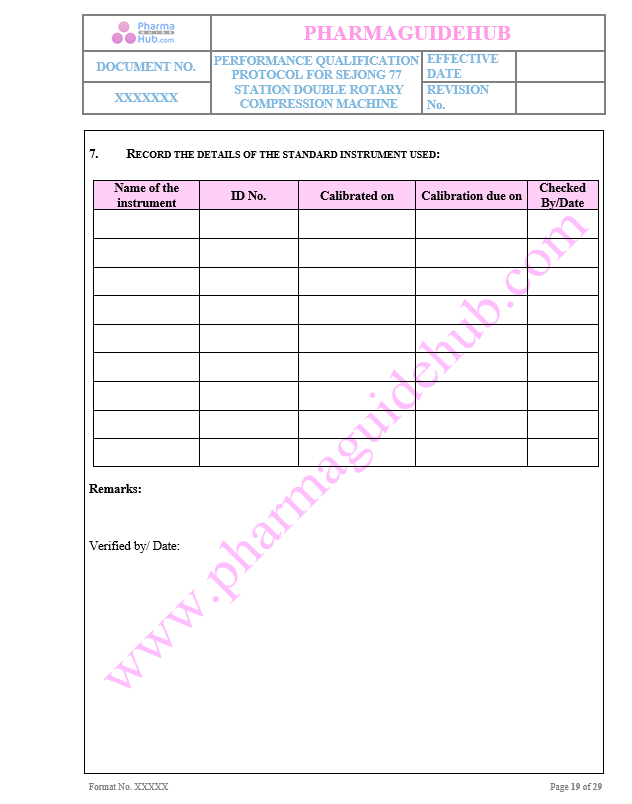

Key Parameter of Below Page

Detail of Instrument Used:

Find below pages for complete protocol:

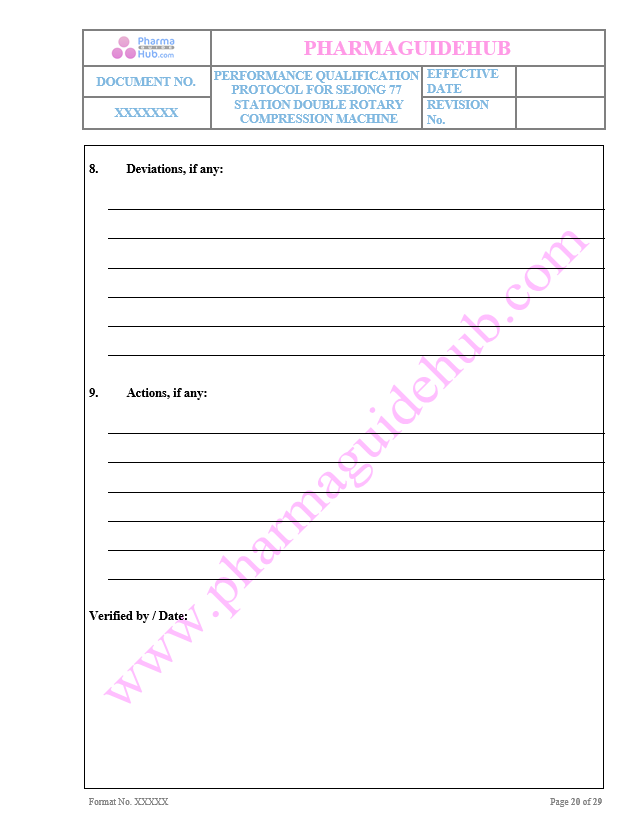

Key Parameter of Below Page

Deviation from pre-approved Protocol

Actions of deviation from pre approved protocol

Find below pages for complete protocol:

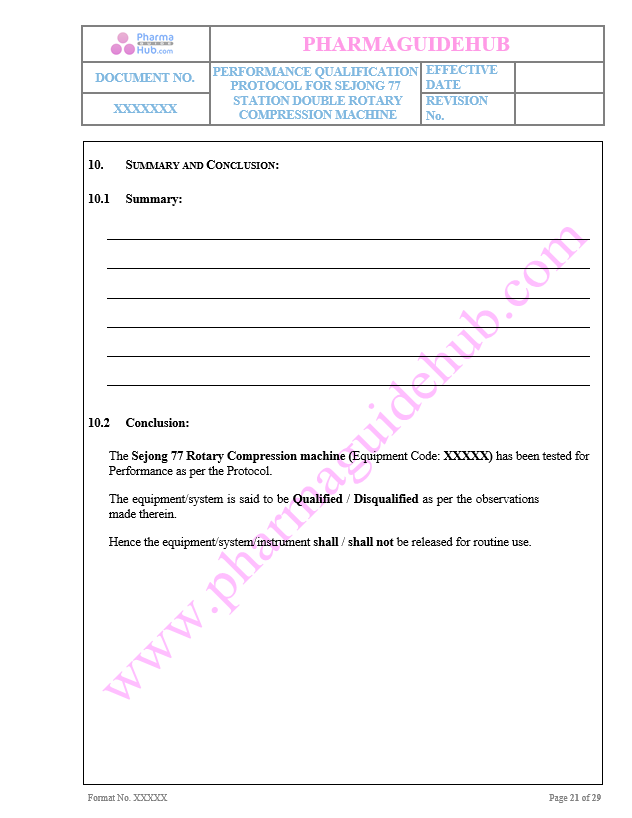

Key Parameter of Below Page

Summary of PQ

Conclusion of PQ

Find below pages for complete protocol:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/performance-qualification-protocol-for-sejong-77-station-double-rotary-compression-machine/

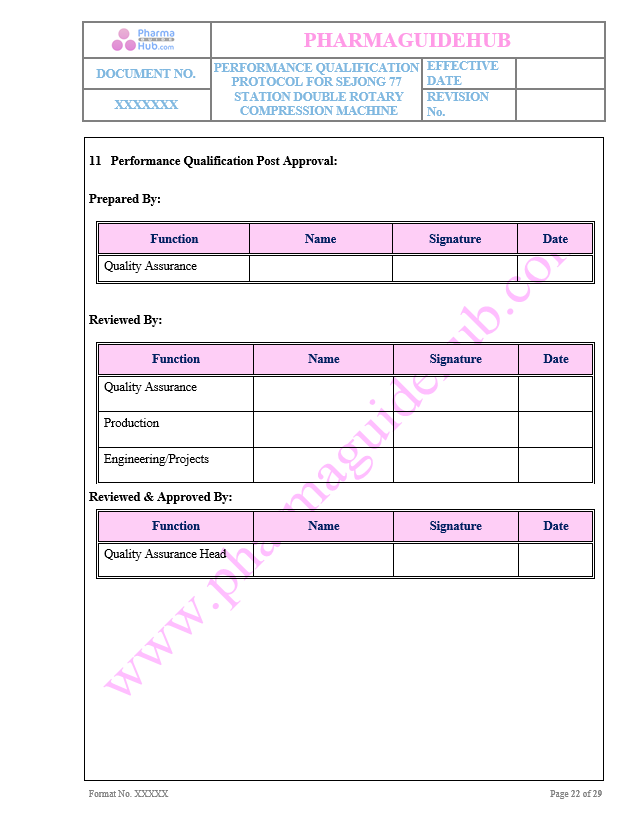

Key Parameter of Below Page:

Post approval of PQ

Find below pages for complete protocol:

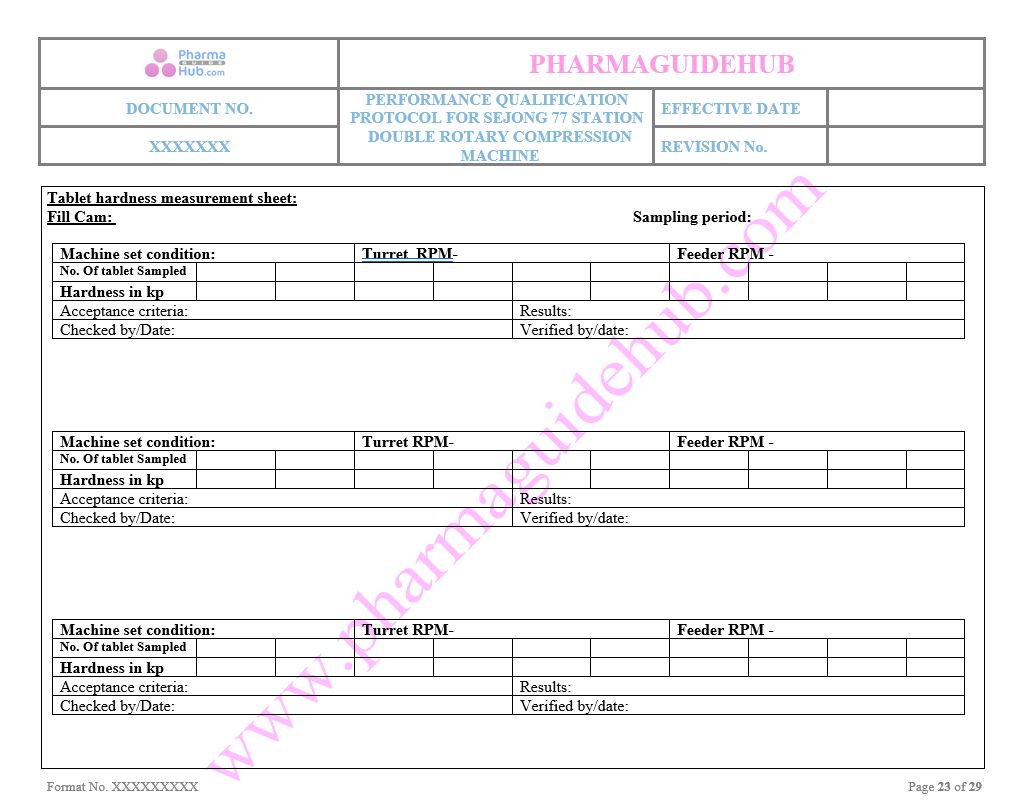

Key Parameter of Below Page:

Tablet Hardness Measurement sheet

Find below pages for complete protocol:

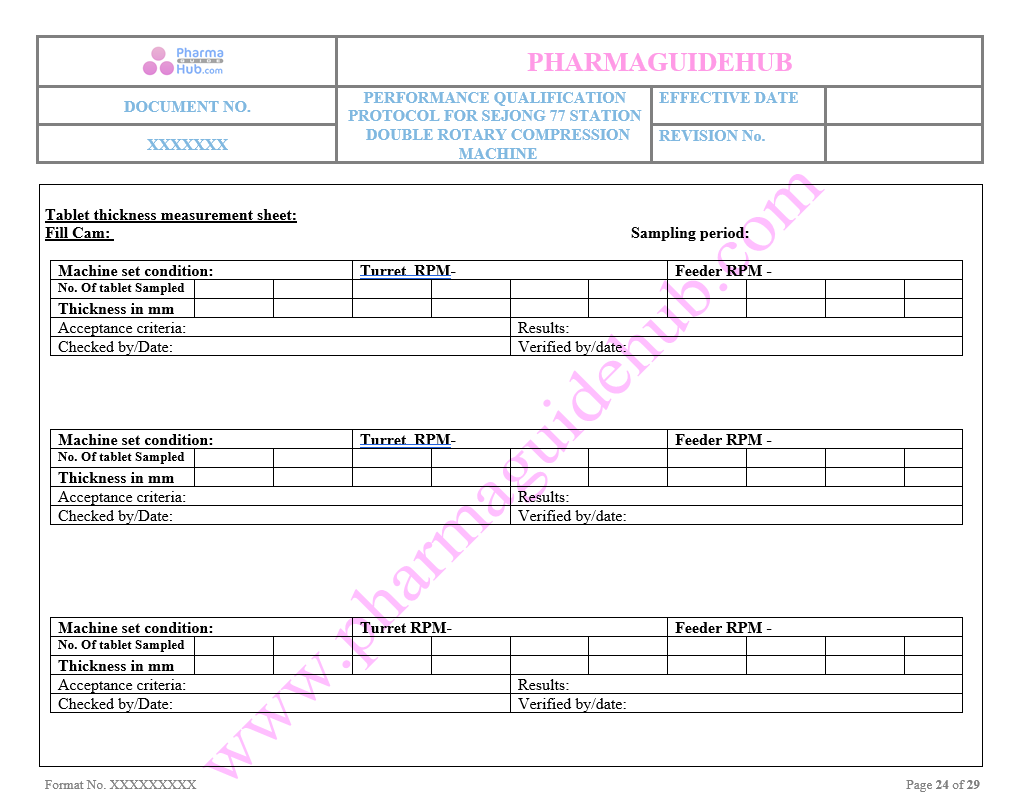

Key Parameter of Below Page:

Tablet Thickness Measurement sheet

Find below pages for complete protocol:

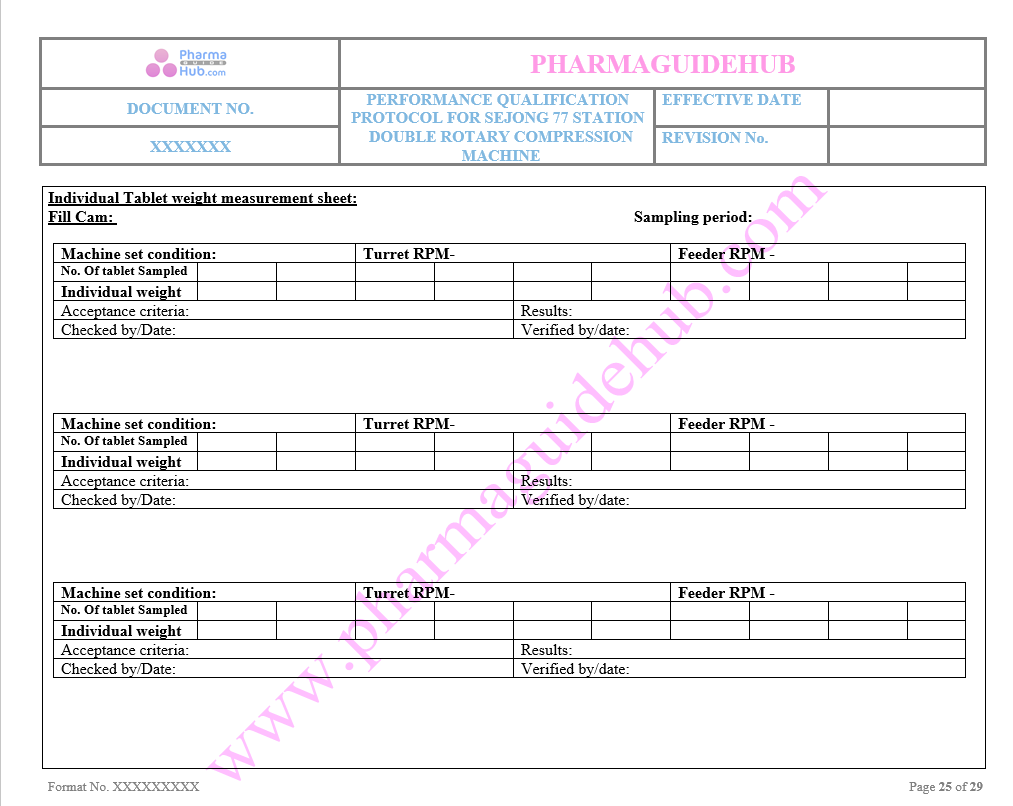

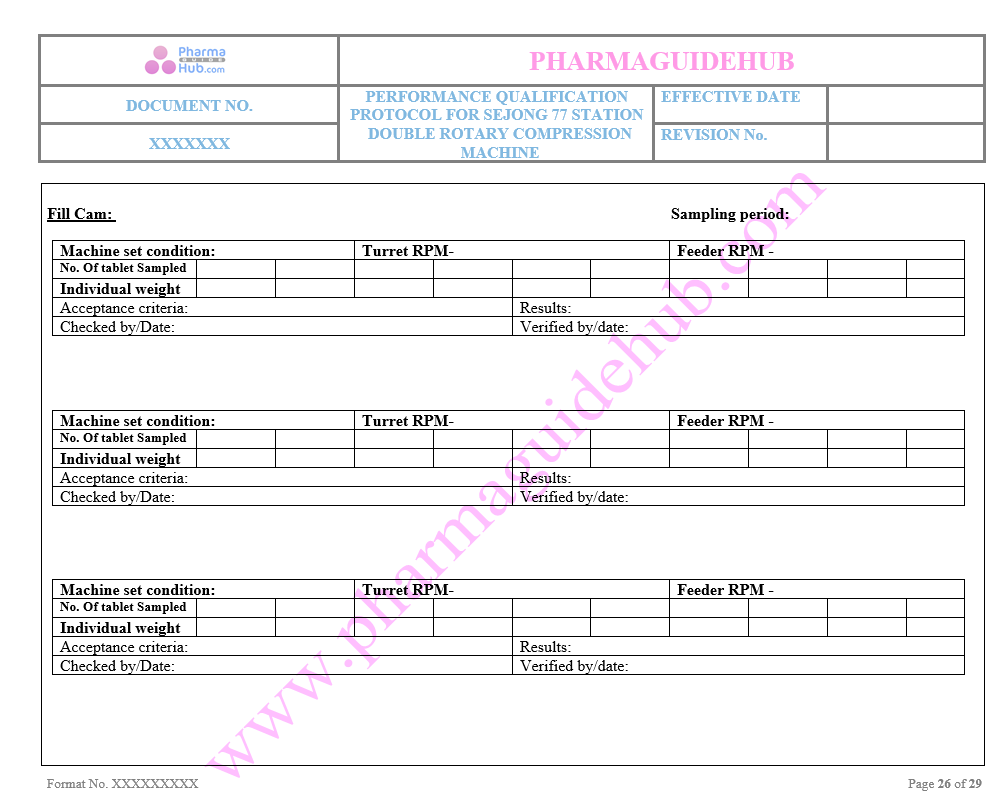

Key Parameter of Below Page:

Individual Tablet Weight Measurement sheet

Find below pages for complete protocol:

Key Parameter of Below Page:

Individual Tablet Weight Measurement sheet

Find below pages for complete protocol:

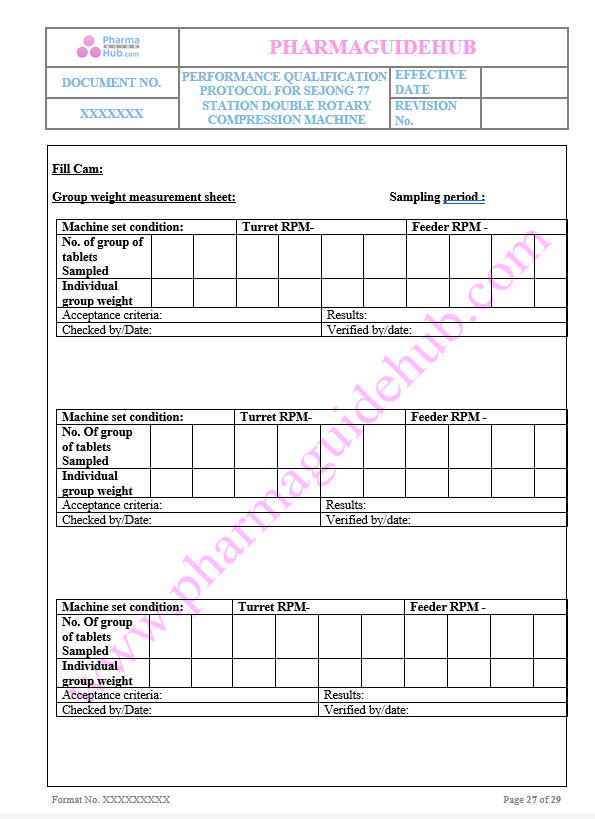

Key Parameter of Below Page:

Group Weight Measurement sheet

Find below pages for complete protocol:

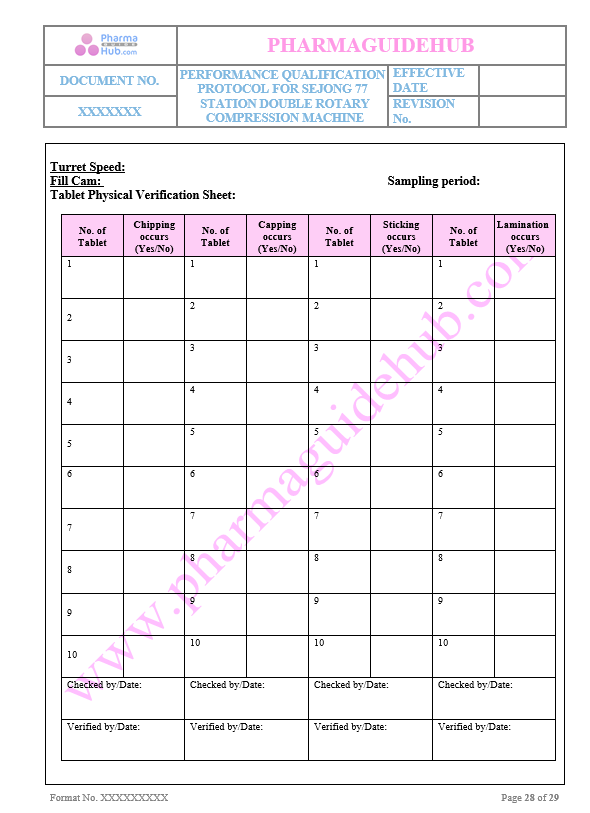

Key Parameter of Below Page:

Tablet Physical Verification sheet

Find below pages for complete protocol:

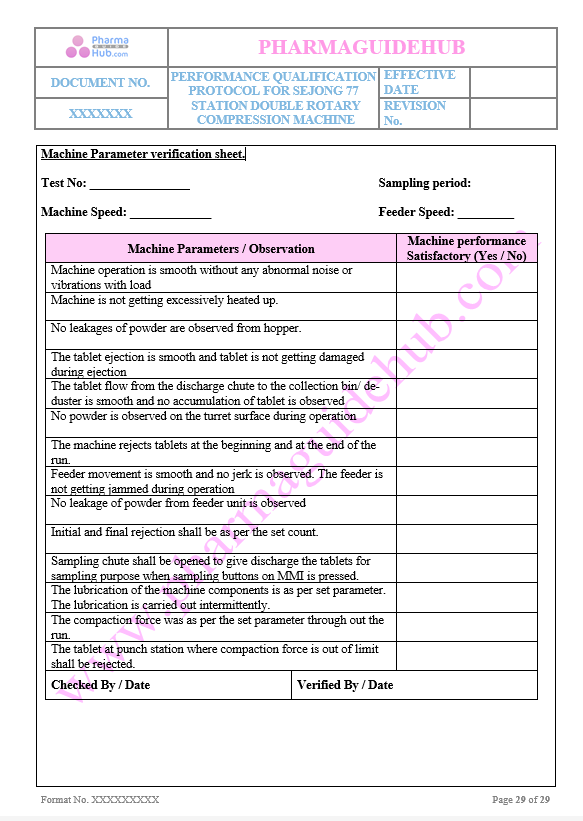

Key Parameter of Below Page:

Machine Parameter Verification sheet

Find below pages for complete protocol:

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/performance-qualification-protocol-for-sejong-77-station-double-rotary-compression-machine/