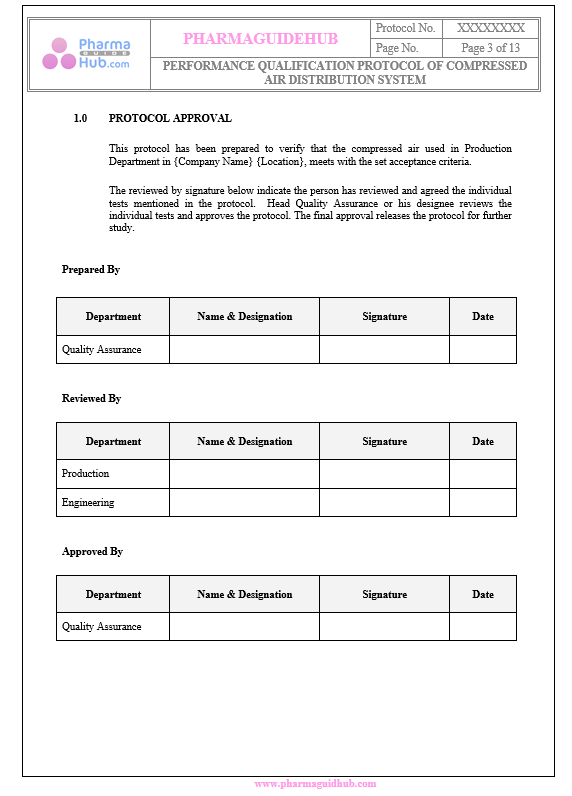

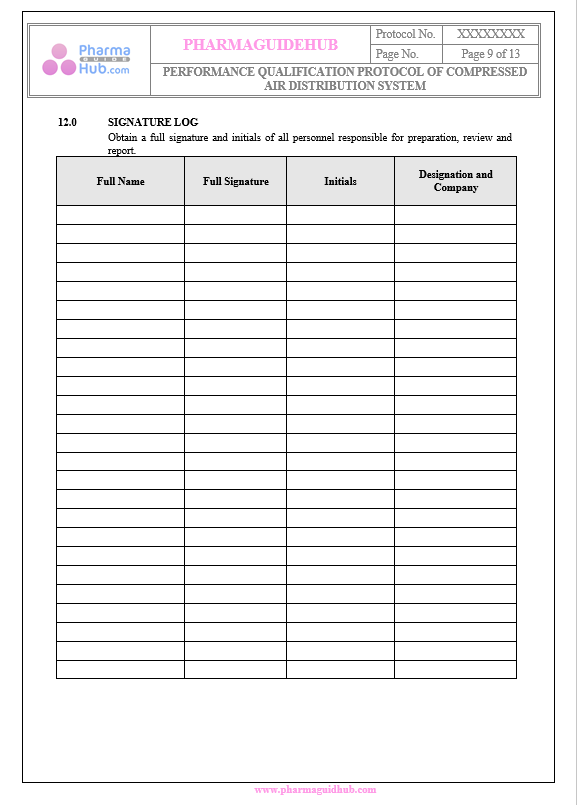

PROTOCOL APPROVAL:

This protocol has been prepared to verify that the compressed air used in Production Department in {Company Name} {Location}, meets with the set acceptance criteria.

The reviewed by signature below indicate the person has reviewed and agreed the individual tests mentioned in the protocol. Head Quality Assurance or his designee reviews the individual tests and approves the protocol. The final approval releases the protocol for further study.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/

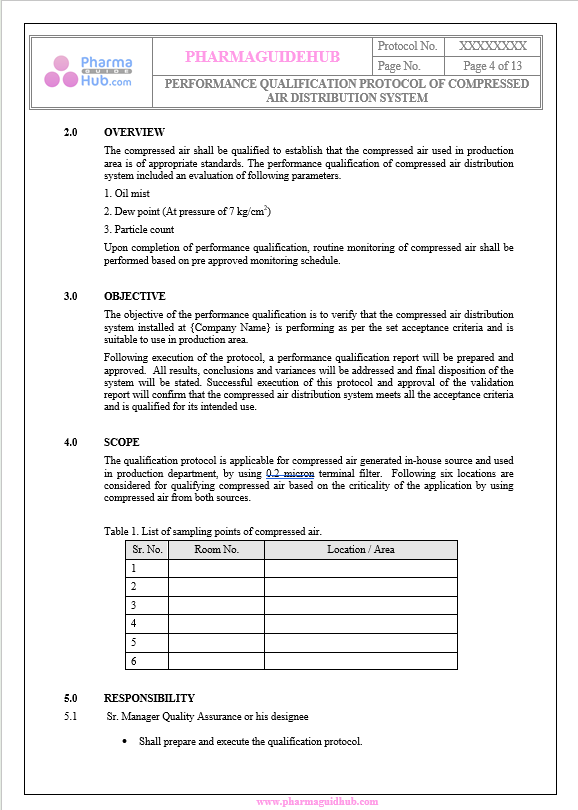

OVERVIEW

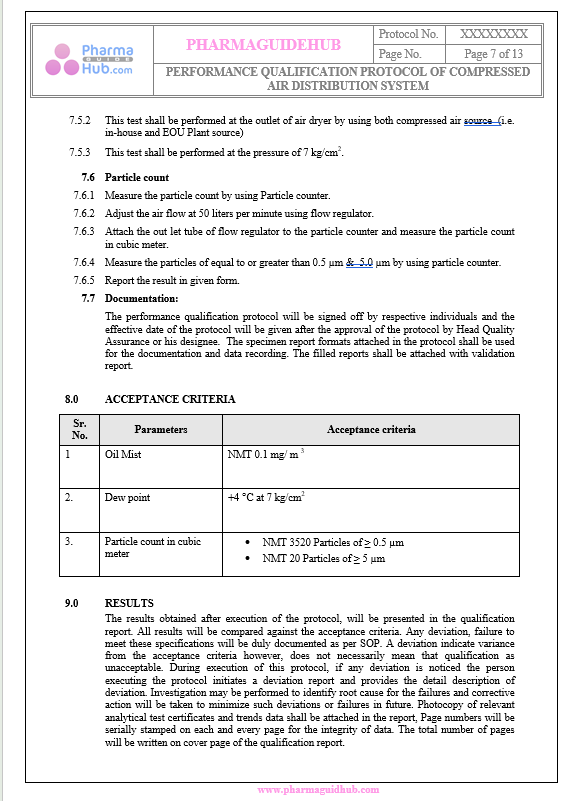

The compressed air shall be qualified to establish that the compressed air used in production area is of appropriate standards. The performance qualification of compressed air distribution system included an evaluation of following parameters.

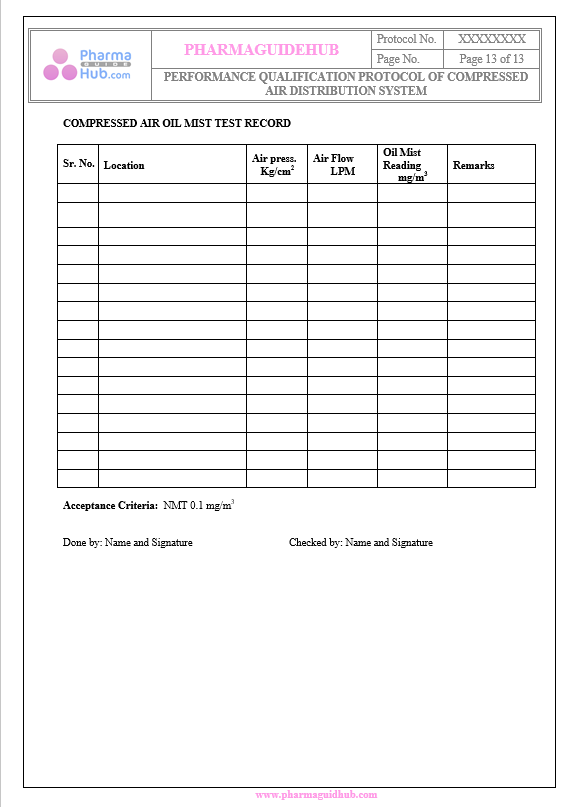

| 1. Oil mist |

| 2. Dew point (At pressure of 7 kg/cm2) |

| 3. Particle count |

Upon completion of performance qualification, routine monitoring of compressed air shall be performed based on pre approved monitoring schedule.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/

Methodology

Equipment & Material

Gas flow regulator

Gas detection tube

Particle counter

Stop watch

Precautions

Ensure gas detection tube is used only once per test. Also ensure proper handling of detector tubes.

Use the tube within the temperature range of 0 – 40 °C.

When cutting the tube ends, wear goggle.

Before sampling, allow to pass the initial compressed air for 3 minutes with valve fully open.

After changing of compressed air source, allow to pass the compressed air for 3 minutes with valve fully open.

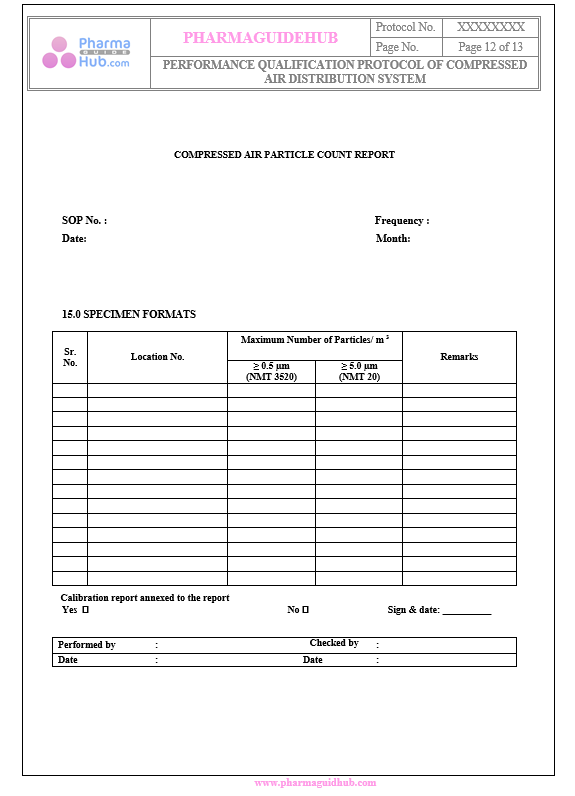

Particle count

Measure the particle count by using Particle counter.

Adjust the air flow at 50 liters per minute using flow regulator.

Attach the out let tube of flow regulator to the particle counter and measure the particle count in cubic meter.

Measure the particles of equal to or greater than 0.5 µm & 5.0 µm by using particle counter.

Report the result in given form.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/qualification-of-protocol-cum-report-of-compressed-air-generation-and-distribution-system/