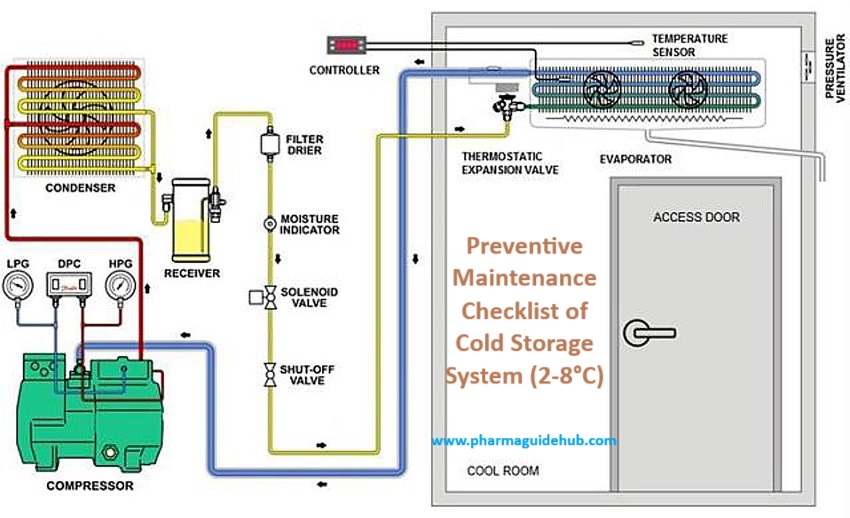

Preventive maintenance of a cold storage system (2-8°C) is crucial to ensure optimal performance, reliability, and longevity. This proactive approach involves regular tasks to prevent equipment failures, reduce energy consumption, and maintain a consistent refrigerated environment. Daily tasks include temperature monitoring and visual inspections, while weekly tasks focus on cleaning and maintenance of condenser coils and air filters. Monthly and quarterly tasks involve inspecting door seals, drain pans, and backup power systems. Semiannual and annual tasks include comprehensive maintenance of the refrigeration system, including oil changes, filter replacements, and inspections. By performing these tasks, users can prevent costly repairs, reduce downtime, and ensure compliance with regulatory requirements. Regular maintenance also helps extend the lifespan of the cold storage system, ensuring continuous storage of temperature-sensitive products within the required temperature range. This proactive approach guarantees optimal system performance and minimizes risks.

| Department: Engineering | Equipment Name: Cold Storage System (2-8°C) | Equip. No./ID: | Frequency: Quarterly | |

| S. No | Check Points | Procedure | Activity | Done By / Date |

| 1 | Check all the bolts and nuts of the cover | By physical verification if found any bolts missing the same shall be replaced and if observed any loosen bolts, tighten them. | ||

| 2 | Check the Indoor unit and outdoor unit. | By Physically verifying the coils and found dust clean with dry Cora cloth or with vacuum cleaner. | ||

| 3 | Ensure the earthing of motor. | Check the earthing wires for proper connection. | ||

| 4 | Check & tighten the motor terminals, control wiring terminals, indication lamps and OLR setting | By physical verification and loosen wires shall be tightened with tester. | ||

| 5 | Check the compressor and Motor Voltage and Amperage | By using a Clamp meter ensure that they are within the acceptable Limit with respect to motor rating. | ||

| 6 | Check the condensate drainage system. | By Physically verifying and if find chock the line should be cleared by blowing air. | ||

| 7 | Check the refrigeration gas | Open the dummy nut and connect the pressure gauge and ensure that the gas pressure should be 60psi at suction line in operation .if less than top up. | ||

| 8 | Check the copper joints | Take a soap solution and apply on the copper joints, if found any leakages then arrest the leaks or repair. If require top up the gas. | ||

Checked By / Date: