OBJECTIVE:

To lay down a procedure for preventive maintenance of Air Handling Unit.

SCOPE:

This SOP is applicable for Preventive Maintenance of Air Handling Unit at {Company Name} {Location}.

RESPONSIBILITY:

Technician- Follow the instruction as per procedure.

Engineering Officer/Executive- Execution as per laid down procedure.

Engineering Head- Technical correction, review, training & monitoring of SOP.

ACCOUNTABILITY:

Engineering Head

Quality Assurance Head

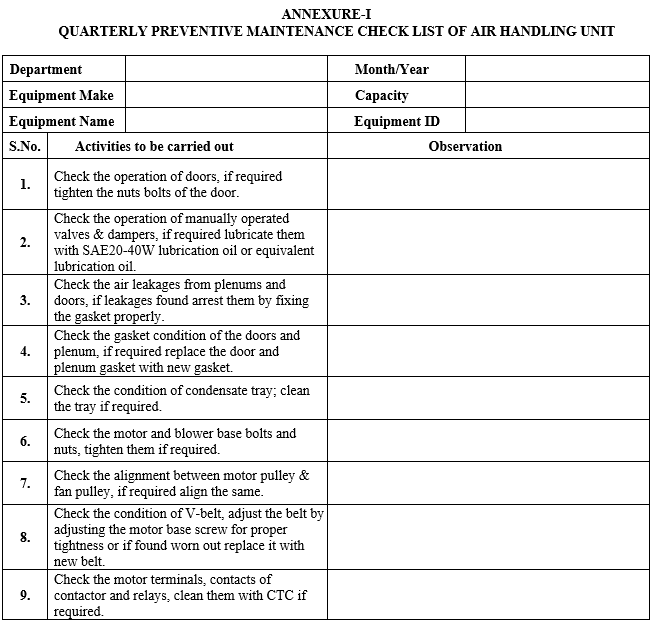

ABOUT HVAC SYSTEM:

HVAC systems are critical in pharmaceutical manufacturing, ensuring product quality and safety. They meticulously control temperature, humidity, and air cleanliness, essential for sensitive drug production. These systems employ HEPA filters to remove airborne particles, preventing contamination. Precise pressure differentials between rooms prevent cross-contamination. Temperature and humidity stability safeguard drug efficacy. Compliance with Good Manufacturing Practices (GMP) is paramount, requiring validated HVAC systems.

PROCEDURE:

Precautions and general conditions:

Switch off the power supply before starting the Preventive Maintenance.

Put status board as ‘UNDER PREVENTIVE MAINTENANCE’ on Equipment.

Refer the Master plan of Preventive Maintenance.

Equipment shall be available for Preventive Maintenance.

Clean oil / grease stains & remove unwanted material, spares after completion of work.

Use necessary safety wears, like gloves, goggles, safety shoe and nose mask if required.

Ensure covers & guards are properly fixed.

Preventive Maintenance frequency of Air handling unit are as per the master Preventive Maintenance Schedule.

Engineering officer/executive shall provide the Preventive Maintenance checklist to engineering technician.

Do the Preventive Maintenance as per checklist / record and update the Preventive Maintenance status.

After completion of work, take the trial for checking smooth operation.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preventive-maintenance-of-air-handling-unit/

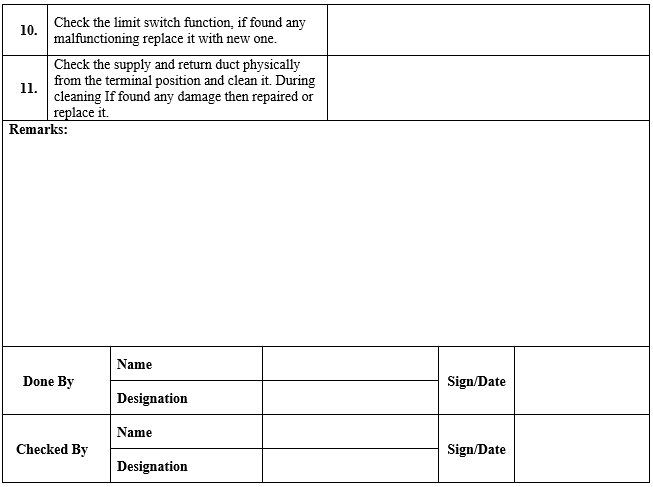

Quarterly Maintenance of Air Handling Unit:

Check the operation of doors & locks, if required tighten the nuts bolts of the door.

Check the operation of manually operated valves & dampers, if required lubricate them with SAE20-40W lubrication oil or equivalent lubrication oil.

Check the air leakages from plenums and doors, if leakages found arrest them by fixing the gasket properly.

Check the gasket condition of the doors and plenum, if required replace the door and plenum gasket with new gasket.

Check the condition of condensate tray; clean the tray if required.

Check the motor and blower base bolts and nuts, tighten them if required.

Check the alignment between motor pulley & fan pulley, if required align the same.

Check the limit switch function, if found any malfunctioning replace it with new one.

Check the condition of V-belt, adjust the belt by adjusting the motor base screw for proper tightness or if found worn out replace it with new belt.

Check the motor terminals, contacts of contactor and relays, clean them with CTC if required.

Check the supply and return duct physically from the terminal position and clean it. During cleaning If found any damage then repaired or replace it.

If the AHU is not connected with chilled water system and having individual cooling system, check the working condition of the cooling system after switching on the system.

Done the Preventive maintenance of Air Handling Unit as per Annexure-I.

Checked by (Reviewed by) sign. in the checklist shall be done on next day by reviewing if the preventive maintenance to be done in the night shift.

REFERENCES:

Not Applicable

ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Quarterly Preventive Maintenance Check list of Air Handling Unit |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

- Controlled Copy No. 01 Quality Assurance Head

- Controlled Copy No. 02 Engineering Head

- Master Copy Quality Assurance Department

ABBREVIATIONS:

SOP : Standard Operating Procedure.

QA : Quality Assurance.

AHU : Air Handling Unit

NA : Not Applicable

MCB : Miniature Circuit Breaker

SAE : Society of Automobile Engineers

CTC : Carbon Tetra Chloride

EG : Engineering

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

ANNEXURE-I

QUARTERLY PREVENTIVE MAINTENANCE CHECK LIST OF AIR HANDLING UNIT

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preventive-maintenance-of-air-handling-unit/