- OBJECTIVE:

To lay down a Procedure for Microbiological Analysis of Packing Material.

- SCOPE:

This SOP is applicable to the Procedure for Microbiological Analysis of Packing Material in Microbiology Department at {Company Name} {Location}.

- RESPONSIBILITY:

Microbiologist / Executive-Microbiology

- ACCOUNTABILITY:

Manager Quality Control

- PROCEDURE:

- Sampling of Packing Material:

- Before starting the sampling, switch on the blower for 15 minutes. After 15 minutes, wipe the LAF work bench with70% IPA and then start the Primary Packaging Material sampling. After completion of work, clean the work station with70% IPA.

- Bring the sample to microbiology department for testing.

- Carry out the test under Laminar Air Flow.

- Analysis:

- For bottles:

- Fill approximately half of the total volume of bottles with sterile Buffered Sodium Chloride Peptone solution. Shake bottles in such a way that internal surface of bottle are to be rinsed properly.

- Pipette out 1 ml of rinsed solution into four labeled Petri plates. Add approximately 15-20 ml of Soyabean Casein Digest Agar into two plates and Sabourauds Dextrose Agar into two other plates.

- Gently swirl plates to mix sample and medium. Allow to solidify.

- Incubate the plates of Soyabean Casein Digest Agar at 30-35°C for 3 days and Sabourauds Dextrose Agar at 20-25°C for 5 days.

CPP Plain 75 MM & CPP Plain 80 MM, Base Foil and Printed Foils :

- Prepare sterilized swab in Buffered Sodium Chloride PeptoneSolution and take swab of 5×5 cm area from the internal surface of Aluminum foil, PVC film, PVDC film with the help of sterilized 5×5 cm template in such a way total 5×5 cm area to be covered properly.

- Deep swab stick in buffered Sodium Chloride Solution tube and vortex it properly.

- Pipette out 1 ml of rinsed solution into four labeled Petri plates. Add approximately 15-20 ml of Soyabean Casein Digest Agar into two plates and Sabourauds Dextrose Agar into two other plates.

- Gently swirl plates to mix sample and medium. Allow to solidify.

- Incubate the plates of Soyabean Casein Digest Agar at 30-35°C for 3 days and Sabourauds Dextrose Agar at 20-25°C for 5 days.

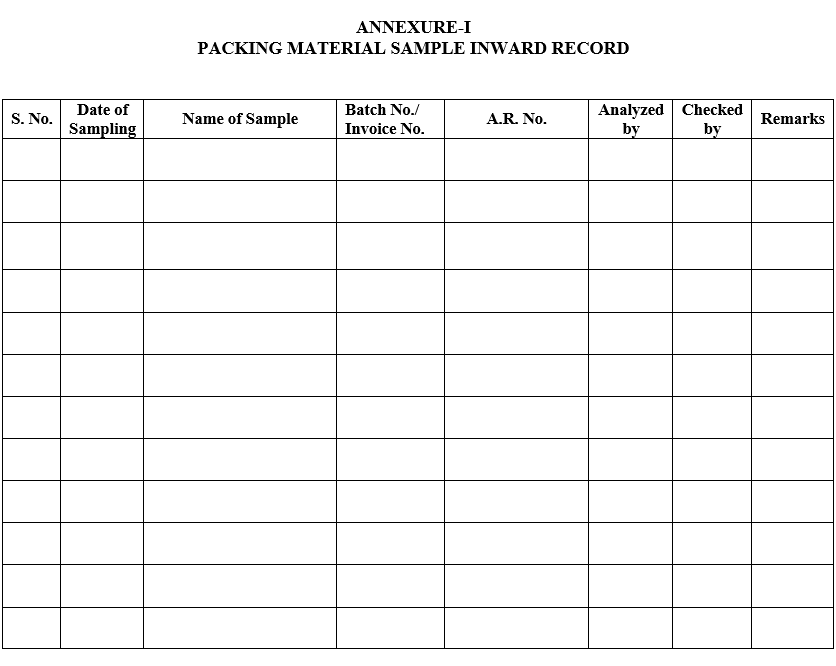

- Microbiologist shall maintain log for inward of Packaging Material as per Annexure I.

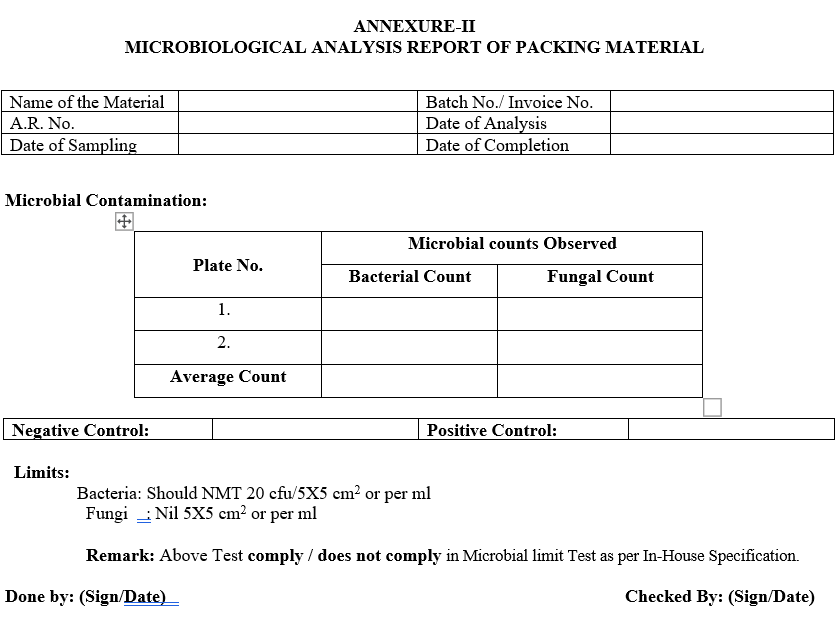

- Count the number of Bacterial and fungal colonies and express the result as count (CFU) / 5×5 cmor per ml as per the Annexure II.

Frequency: Initial three consignments of every new vender and after every three month.

Limits/ Acceptance Criteria:

- Bacteria: Should Not more than 20 CFU/5X5 cm or per ml

- Fungi : Should Not more than 2 CFU/5×5 cm or per ml

- Negative Control: Should not show the growth after 48 Hours.

REFERENCES:

In-House

ANNEXURES:

| ANNEXURE No. | NAME OF ANNEXURE |

| Annexure-I | Packing Material Sample Inward Record. |

| Annexure-II | Microbiological Analysis Report of Packing Material |

DISTRIBUTION:

| Control copy No. 1 | : | Manager Quality Assurance |

| Control copy No. 2 | : | Manager Quality Control |

| Master copy | : | Quality Assurance Department |

ABBREVIATIONS:

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

| MB | : | Microbiology |

| °C | : | Degree Centigrade |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Change | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Recorded Manual |

ANNEXURE-IPACKING MATERIAL SAMPLE INWARD RECORD

ANNEXURE-II

MICROBIOLOGICAL ANALYSIS REPORT OF PACKING MATERIAL