- OBJECTIVE:

- To lay down the procedure for operation of dispensing booth for the raw and packaging material.

- SCOPE:

- This SOP is applicable for the operation of dispensing booth for the raw and packaging material at {Company Name} {Location}.

- RESPONSIBILITY:

- WH Executive/Designee – shall be responsible to follow the procedure as per SOP.

- Head Warehouse – is responsible for compliance of the SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- OPERATION OF LAF:

- The dispensing booth and room should be cleaned prior to the start of dispensing activity daily.

- Verify the Preventive Maintenance Status of LAF.

- Ensure the cleanliness of side panels, grills and balance wherever applicable.

- Ensure minimum items should be stored under the LAF as required for dispensing.

- Ensure AHU of dispensing room is switched “ON” at least 30 minutes prior to commencement of the operations.

- Do not open the container inner pack outside the safe working zone.

- Switch on the LAF station, and light switches of Dispensing booth wherever applicable.

- Wait for 15 minutes after switching on the LAF station to stabilize the system prior to start the dispensing activity and record the LAF switched on time in the Format.

- Check the 10.0µ, 5.0µ & HEPA (0.3µ) filter pressure differentials indication level and record the filter pressure differentials.

- Limits of LAF:

10 µ (Pre Filter) – 1 to 4 mm of WC

5.0 µ (Fine Filter) – 4 to 10 mm of WC

0.3 µ (HEPA) – 10 to 25 mm of WC

- In case of any power failure/LAF breakdown, stop the activity and inform to the Engineering Department, after rectification once again take Line Clearance from IPQA and start the Dispensing.

- After ensuring required environment conditions and Differential Pressure of Dispensing area/LAF are within the specified limits.

- The Warehouse Executive/Designee shall ensure that the material, which is going for dispensing, shall be placed at respective designated area.

- Run the LAF station till dispensing is completed, and then switch “OFF” LAF station and record in the Format.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Usage and cleaning record of Dispensing Booth & Room in Warehouse |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Warehouse

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| QA | : | Quality Assurance |

| LAF | : | Laminar Air Flow |

| AHU | : | Air handling unit |

| WC | : | Water Content |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

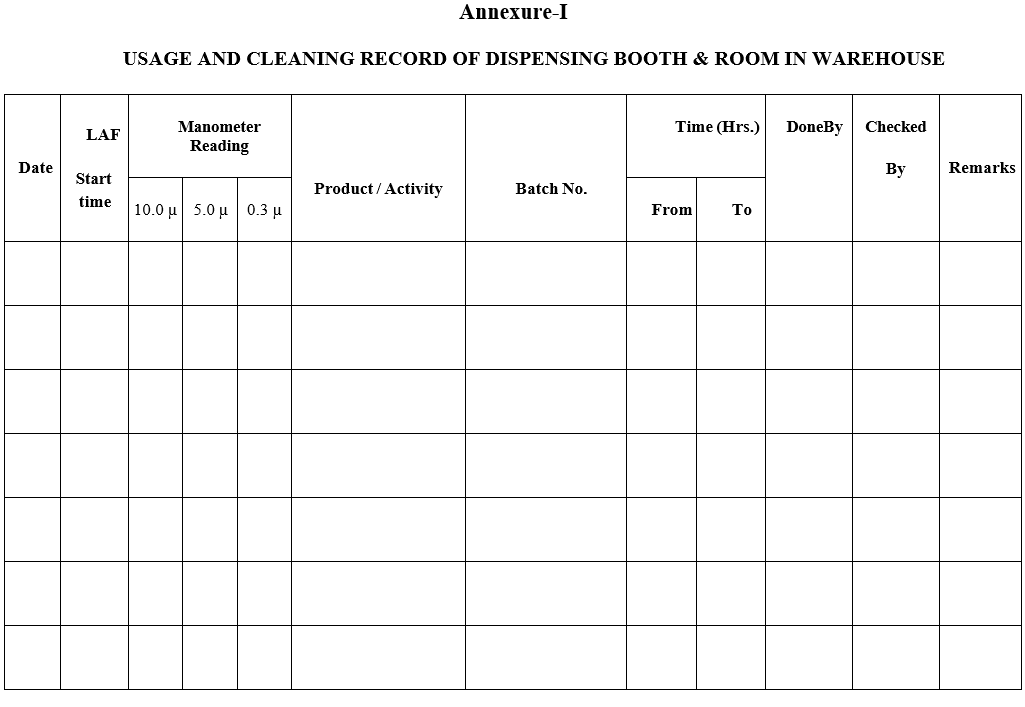

Annexure-I

USAGE AND CLEANING RECORD OF DISPENSING BOOTH & ROOM IN WAREHOUSE

Frequently Asked Question?

1. What are the key steps involved in preparing the LAF for dispensing activity?

Answer: The key steps include:

- Cleaning the dispensing booth and room

- Verifying the LAF’s preventive maintenance status

- Ensuring cleanliness of side panels, grills, and balance

- Minimizing items stored under the LAF

- Switching on the dispensing room’s AHU 30 minutes prior

- Waiting 15 minutes after switching on the LAF to stabilize

2. What are the acceptable pressure differential ranges for the LAF filters?

Answer:

- 10 µ (Pre Filter): 1 to 4 mm of WC

- 5.0 µ (Fine Filter): 4 to 10 mm of WC

- 0.3 µ (HEPA): 10 to 25 mm of WC

3. What actions should be taken in case of a power failure or LAF breakdown?

Answer:

- Stop dispensing activity immediately

- Inform the Engineering Department for rectification

- Obtain line clearance from IPQA before restarting

- Ensure environmental conditions and pressure differentials are within limits before restarting

4. Who is responsible for ensuring materials are placed in the designated area for dispensing?

Answer:

- The Warehouse Executive/Designee

5. When should the LAF station be switched off?

Answer:

- After dispensing is completed