OBJECTIVE:

To lay down a procedure for calibration of RPM Indicator.

SCOPE:

This SOP is applicable to the procedure for calibration of RPM Indicator at {Company Name} {Location}.

RESPONSIBILITY:

Officer/Executive/Designee: shall be responsible for following the procedure as per SOP.

Engineering Head/designee is responsible for compliance of SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

PROCEDURE:

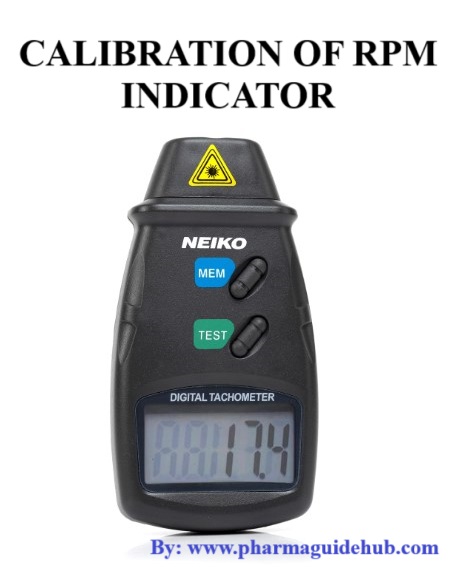

Ensure the Standard Photo/Contact Tachometer and Digital stopwatch is within the validity period.

Ensure the written requisition is obtained from the concerned user department (wherever applicable).

Ensure that the Equipment RPM range up to 50rpm (wherever applicable), calibration shall be performed by using Standard Digital stopwatch.

Switch ON the equipment and set the RPM, the same time start the Standard Digital stopwatch and manually count the equipment RPM.

Observe and note down the readings in the format of SOP.

Ensure that the Equipment RPM range is above 50rpm, calibration shall be performed by using Standard Photo/Contact Tachometer.

Find the proximity sensor location from where the RPM indicator senses.

Switch OFF the Equipment and select the contact/photo of the Standard tachometer whichever is applicable (if selected photo type uses the reflective type).

Switch ON Tachometer to contact with the rotatory (rotatable) part of the equipment by using the selected Contact type.

Switch ON the equipment and set the RPM and start the rotating part and note down the reading with the Standard tachometer.

Allow a few seconds for the indicator to equalize the reading of Standard and specimen RPM Indicator.

In case any discrepancy is observed in the under calibrating RPM indicator then adjust the Indicator for necessary correction. (wherever applicable).

Follow the same mentioned in above step and take five intermittent readings of Particular RPM Indicator in the equipment and Standard RPM Indicator (Photo/Contact Tachometer).

Observe and note down the readings in the format.

If the results are satisfactory then affix the “CALIBRATED” status label as per SOP “Calibration of Equipments/Instruments.”

If the results are not satisfactory then affix the “CALIBRATION FAILED” status label as per SOP.

If an error is not rectified with the under calibrating RPM indicator then replace the same Indicator with another duly calibrated.

The acceptance criteria for RPM instruments are +/- 1RPM (up to 100RPM) and above 100RPM instruments are +/- 1% RPM if the least count of the instrument is more than the acceptance criteria then its least count shall be taken as acceptance criteria.

Standard Digital Photo/contact tachometer and Digital stopwatch shall be calibrated once in a year.

The RPM instruments are calibrated as per the Master calibration schedule.

REFERENCES:

Not Applicable

ANNEXURES:

Not Applicable

DISTRIBUTION:

Controlled Copy No. 01 : Head Quality Assurance

Controlled Copy No. 02 : Head Engineering

Master Copy : Quality Assurance Department

ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| RPM | : | Revolution per Minute |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable |