OBJECTIVE:

To lay down a procedure for cleaning of Bung processor cum steam sterilizer.

SCOPE:

This SOP is applicable for cleaning of Bung Processor Cum Steam Sterilizer for Production dry powder Injection.

RESPONSIBILITY:

Technical Assistant –Production shall follow the procedure mentioned in SOP.

Executive – Production shall ensure the compliance as per SOP.

ACCOUNTABILITY:

Production Head

Head Quality Assurance

PROCEDURE:

Cleaning of Bung Processor Cum Steam Sterilizer is to be done before starting the day’s first sterilization cycle and if required in between the other cycles.

Cleaning of Bung Processor Cum Steam Sterilizer shall be done from the equipment washing & sterilization room side only.

Ensure that the cooling area side door is closed.Open the equipment washing & sterilization room side door by pressing push button switch provided on the control panel.

Clean the Bung Processor Cum Steam Sterilizer chamber and door gasket with the help of a lint free duster soaked in Purified Water.

Clean the outer surface of Bung Processor Cum Steam Sterilizer body with a lint free duster soaked in Purified Water followed by dry moping with lint free duster.

Clean the trolleys and carriages with lint free duster soaked in Purified Water everyday before loading into the sterilizer.

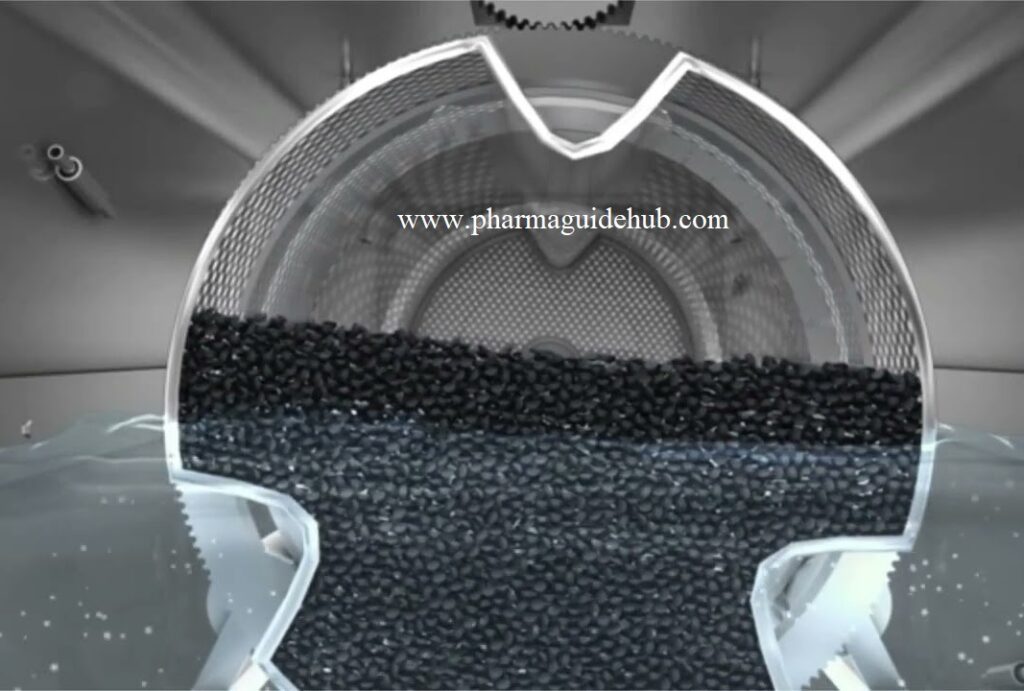

Clean the SS perforated boxes with Purified Water everyday before use.

Clean the pipelines from outside with lint free duster soaked in Purified Water at least once in a month.

Dismantle the condensate drain line and steam trap and flush with Purified Water once in every month.

Record the details of cleaning operation in the operation and cleaning record as per SOP and get it checked by concerned Supervisor / Officer.

Note: Cleaning with wet lint free duster should not be done before taking the cycle for vacuum leak test. If at all cleaning is necessary before vacuum leak test, only dry lint free duster should be used.

REFERENCES:

Not Applicable

ANNEXURES:

Not Applicable

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

Controlled Copy No. 01 Head Quality Assurance

Controlled Copy No. 02 Head-Production

Master Copy Quality Assurance Department

ABBREVIATIONS:

SOP : Standard Operating Procedure

SS: Stainless Steel

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |