In the pharmaceutical industry, stamps play a crucial role in maintaining quality control and ensuring regulatory compliance. These stamps are used to mark documents and materials with essential information, such as “APPROVED,” “REJECTED,” “AUTHORIZED,” and “MASTER.” This system allows for quick and clear communication of the status of various items throughout the manufacturing and packing processes.

Training Copy stamp

This Stamp has been used on Training copy of SOPs.

Master Copy stamp

This stamp has used to generate the master copy of document.

CONTROLLED COPY

This stamp is use to generate the control copy from master document.

ISSUED BY QA stamp

This stamp has been affixed on issed copy.

Display Copy stamp

This stamp has been used for display copy of SOP.

Uncontrolled Copy stamp

This stamp has affixed when any document has share out side the premises.

Obsolete Copy stamp

This stamp has been affixed on master copy when new version of documents has been introduce.

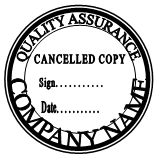

Cancelled stamp

When any generated document need to cancel then cancelled stamp has been used.

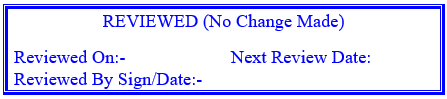

Reviewed stamp

When in a document any changes are not required and its validity has expired, to extend the validity of the same document, a reviewed stamp has been used.

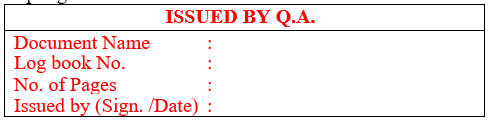

ISSUED BY Q.A.

This stamp has used during the issuance of log book.

ADDITIONAL PAGE STAMP

This stamp has been used when an additional page has been issed.

REFERENCE COPY

This stamp has been issued for the reference of the master document photocopy.

For Complete procedure of stamps find the below SOPs:

SOP of SOP (SOP on SOP in Pharmaceutical)

PROCEDURE FOR DOCUMENTATION AND DATA CONTROL IN PHARMACEUTICAL INDUSTRY