OBJECTIVE:

To lay down the procedure for Usage of numbered strip seals in the Process area.

SCOPE:

This SOP is applicable to usage of numbered strip seals in the Process area.

RESPONSIBILITY:

- Initiator Officer/Designee: Production shall perform the operation activity as per SOP.

- Initiator Executive/Designee: Production shall ensure the compliance of the SOP.

ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

About Numbered Strip

In pharmaceutical manufacturing, numbered strip seals play a crucial role in ensuring product integrity and traceability. These seals are applied to critical equipment and access points within the process area. Each seal has a unique number, allowing for meticulous record-keeping. During routine inspections and after maintenance activities, seals are checked for tampering or unauthorized access. If a seal is broken or missing, it immediately alerts personnel to a potential breach in aseptic conditions or equipment integrity. This system enhances process validation, minimizes contamination risks, and facilitates thorough investigations in case of any deviations, ultimately safeguarding product quality and patient safety.

PROCEDURE:

Strip Seals at Blending Stage:

Only the numbered strip seals shall be used for sealing the Bins.

Strip seals should be used for sealing the lid of the bin after completion of the blending.

The strip seal number shall be recorded in the Blend BMR.

If the blend is unloaded in the H.D.P.E. container then the lid should be closed and sealed with numbered seals in such a way that the lid shall not open unless the strip seals are broken.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/usage-of-numbered-strip-seals-in-the-process-area/

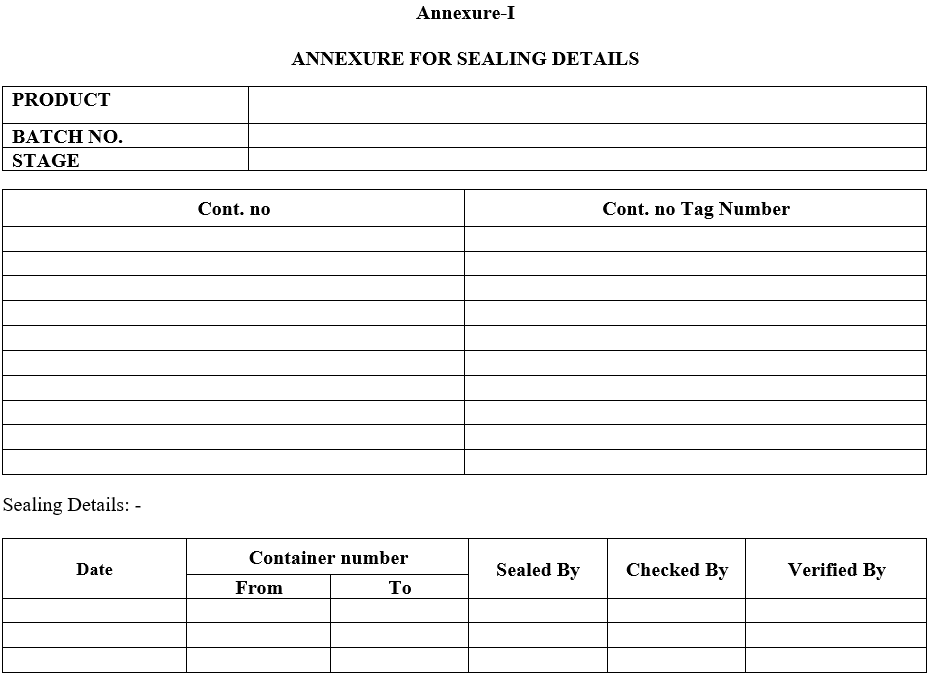

The seal number shall be entered in the annexure provided.

Before starting the compression, the seal number shall be checked by production executives and verified by IPQA executive along with the annexure provided.

The strip seal of the bin shall be intact till the completion of compression activity. If any discrepancy is observed, inform the IPQA Executive/Designee and Production In charge.

Strip Seals at Compression/Coating/Thickness Sorting/ Inspection Stage and Capsule Filling Stage:

After completion of the COMPRESSION/COATING/THICKNESS SORTING/ INSPECTION STAGE AND CAPSULE FILLING STAGE weigh the individual container, affix ERP generated Product Label or duly filled Product Label.

Put the Nylon tags, nylon threads or numbered nylon tags to the polybag of the individual Crates.

Close the top lid of the crates and seal the numbered strip seal to both the side of the crates in such a way that the lid shall not open until the strip seals are broken.

Record the strip seal number in the annexure provided.

If more than one polybag is stored in a container, all the polybags should be tied with nylon tags, nylon threads or numbered nylon tag.

During line clearance for packing these numbers shall be cross verified by the packing executives.

If any discrepancy observed, inform to the IPQA executive and the production In charge.

Note: Strip seals should use for all the products

REFERENCES:

Not Applicable

ANNEXURES:

| Annexure Number | Title of annexure |

| Annexure-I | Annexure for Sealing Details. |

ENCLOSURES: SOP Training Record.

DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Production

- Master Copy : Quality Assurance Department

ABBREVIATIONS:

| PD | : | Production |

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| BMR | : | Batch manufacturing record |

| HDPE | : | High density polyethylene |

| IPQA | : | In process Quality Assurance |

REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Written Manual |

Annexure-I

ANNEXURE FOR SEALING DETAILS

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/usage-of-numbered-strip-seals-in-the-process-area/