- OBJECTIVE:

- To lay down the procedure for operation of Friabilator Make – Electro lab.

- SCOPE:

This SOP is applicable to the operation of Friabilator Make – Electro lab at I M Healthcare Pvt. Ltd. Baddi.

- RESPONSIBILITY:

- Officer/Executive/Designee Quality Control – Shall be responsible for operation as per SOP.

- Head/Designee Quality Control – Shall be responsible for ensuring compliance as per SOP.

- ACCOUNTABILITY:

QA Head shall be Accountable for implementation of SOP.

- PROCEDURE:

- A friabilator is a laboratory instrument used to measure the resistance of tablets to mechanical wear and tear caused by rubbing, impact, and chipping during handling, packaging, and transport.

- It simulates the physical stresses that tablets experience in the market, helping to ensure their quality and performance.

- Before starting the operation check the cleanliness of the working area, instrument and calibration Status.

- Connect the pin to the power supply.Switch ‘ON’ the main power.

- At the power ON, drum will initialize itself to the loading position.

- The display will now show start.Slide the tablets gently into the drum from the side slit provided on the drum.

- Select the ‘TIME MODE’ or ‘REVOLUTION COUNT MODE’ as desired by pressing the ‘TIME/COUNT’ key respectively.

- The mode indicator led will indicate the selected mode.

- The display will show the previous time or count values.

- Enter the desired value for the set mode and press the enter key to register the value.Press ‘RUN’/ ‘HALT’ key to start the test.

- The ‘DRUM’ will start rotating.

- The display will show elapsed time or count depending on the mode selected.

- When the test is over, the drum rotates in the reverse direction discharging the tablets into the tray.

- Collect the sample from the tray and calculate according to the STP.

- The drum then oscillates gently to make sure that all tablets are discharge into the tray.

- The test over is indicated by an audible beep and the display will show ‘END’.Switch off the instrument in case during the test if the user needs to change the time / count value press run/halt key.

- The instrument is now in halt state, which is indicated by the halt, led on the front panel.

- If the value fed is below the elapsed time or count then the instrument would prompt Err, on the display. Pressing the run / halt key again to continue the test.

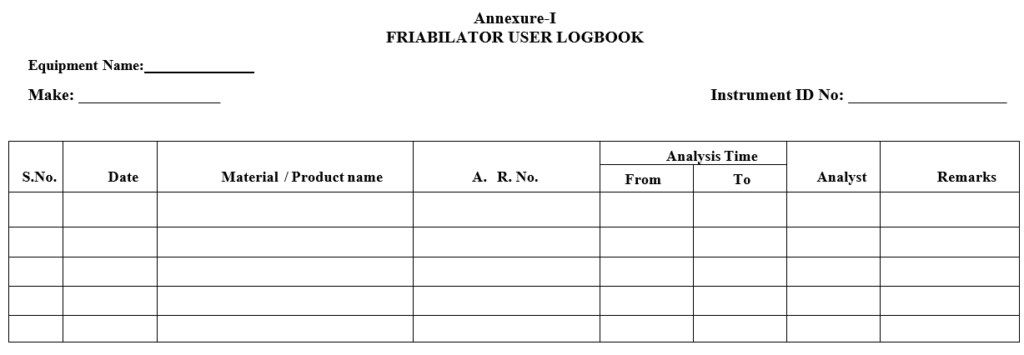

- Enter the details of the usage in the logbook as per Format-I.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-friabilator-make-electrolab/

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Friabilator user logbook |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 : Head Quality Assurance

- Controlled Copy No. 02 : Head Quality Control

- Master Copy : Quality Assurance Department

- ABBREVIATIONS:

| No. | : | Number |

| SOP | : | Standard Operating Procedure |

| STP | : | Standard Test Procedure |

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To Be Write Manual |

Annexure-I

FRIABILATOR USER LOGBOOK

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-friabilator-make-electrolab/