- OBJECTIVE:

To lay down a procedure for Replacement of Micron cartridge filters.

- SCOPE:

This SOP is applicable for Replacement of Micron cartridge filters at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible to perform the activity as per the SOP.

- Executive – Engineering is responsible to ensure the compliance of the SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Cartridge filters are cylindrical or pleated filtration devices used to remove impurities and particles from liquids or gases. They consist of a filter element housed within a casing made of various materials like paper, polyester, or cotton. The fluid to be filtered passes through the filter element, which traps and holds the impurities, allowing only the clean liquid or gas to pass through.

- PRECAUTIONS TO BE TAKEN BEFORE REPLACEMENT OF CARTRIDGE FILTERS.

- Ensure that the Chlorinated Raw water storage tank discharge valve is closed.Ensure that the Pre UF permeated storage tank discharge valve is closed.Ensure that the area is clean.

- 50 MICRON FILTER (107.4-MCF-01)Open the filter housing and remove the filter element from the housing.Drain out the water inside the housing.Clean the filter housing by flushing with purified water.Replace the O ring with a new one if required.Assemble the new filter element of same rating and specification in the housing and fix the housing.Ensure that there is no water leakage from filter housing.

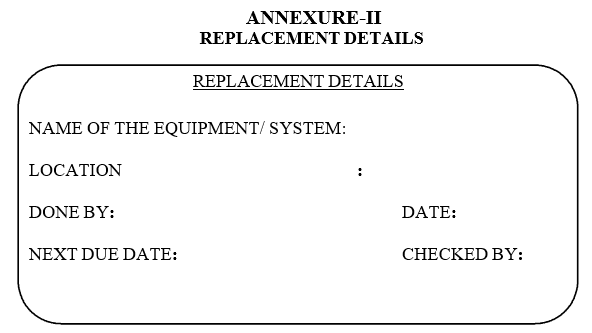

- 5 MICRON FILTER Ensure that the RO system is in OFF mode from the PLC panel.Open the filter housing and remove the filter element from the housing.Drain out the water inside the housing.Clean the filter housing by flushing with purified water.Replace the O ring with new one if required.Fix the new filters and assemble the housing.Close the drain plug.Ensure that there is no water leakage from filter housing.Record the Filter replacement details as per Format – 1.After completion of filter replacement, the label shall be updated as per Annexure-II.

- Frequency:

Replacement of Micron Cartridge filters shall be carried out once in six months along with the second quarterly preventive maintenance of water system.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

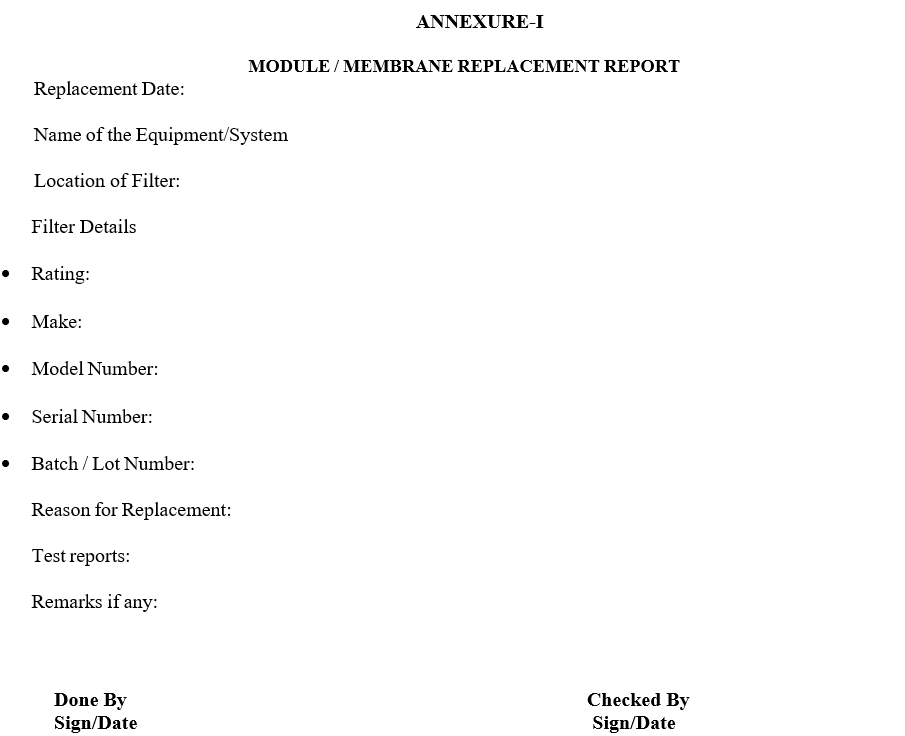

| Annexure-I | Micron cartridge filters Replacement record |

| Annexure-II | Label for Replacement Details |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

RO : Reverse osmosis

SOP : Standard Operating Procedure

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

MODULE/MEMBRANEREPLACEMENT REPORT

ANNEXURE-II

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/replacement-of-cartridge-filters/