- PROCEDURE:

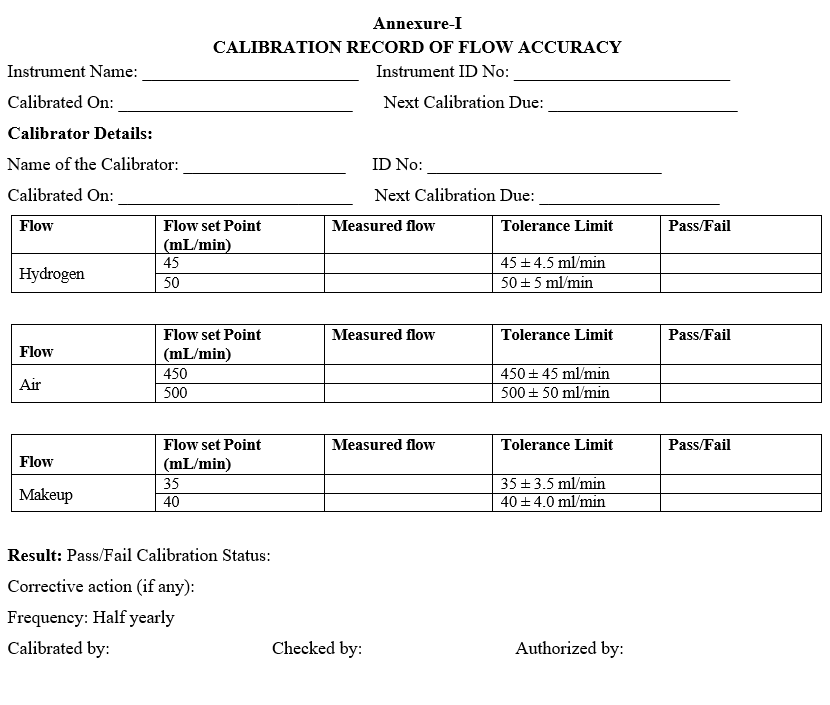

- CALIBRATION OF FLOW ACCURACY:

- Select detector flow and set it to the specified value listed in the result Table (Annexure-I)

- Ensure that all other detector flows are “OFF”.After completing appropriate preparation steps for the calibration mass flow meter being used ( i.e. Gas selection, purge, and zero).

- Connect the flow meter to the detector exit and measure flow.

- Allow time for flow meters” reading to stabilize.

- Record the flow value displayed on GC front panel in the results table.

- Record the measured flow value displayed on flow meter in results table (Annexure-I).

- Calculate the flow difference between displayed value and measured value and record the results table (Annexure-I).

- Turn flow OFF.Repeat the steps above for each remaining detector flow.After all flows have been measured.

- Remove the flow Cap from the detectors base.

- Acceptance criteria: the difference between measured flow and set flow should not be more than ± 10%.

- Record the details in annexure-I.

- Calibration schedule: Once in six months and after any major maintenance Job.

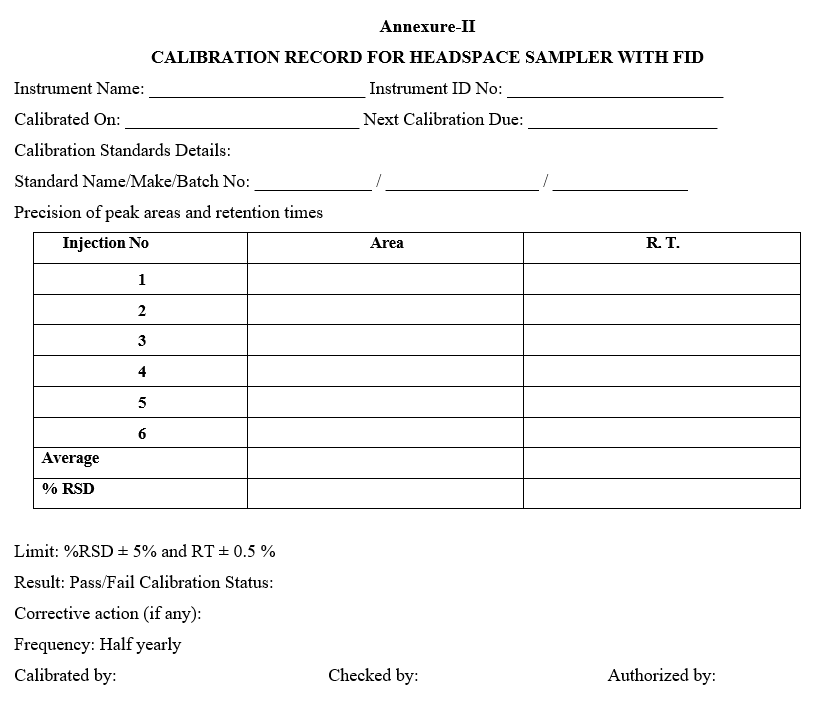

- CALIBRATION OF HEADSPACE SAMPLER WITH FID DETECTOR:

- Fix the column from capillary inlet to FID.

- Chromatographic parameters

- Column: Fused silica column 30 m long 0.32 m internal diameter with 1.8 micrometers film of 6% Cynopropyl Phenyl. 94% dimethyl polysiloxane.

- Inlet temperature 120°C

- Carrier gas: Helium

- Oven temperature: 60°C (Iso thermal)

- Flow mode: Constant Flow

- Detector Temperature: 200°C

- Column Flow: 0.8 ml/min

- Hydrogen Flow: 45 ml/min

- Air flow :450ml/min

- Make up flow :30ml/min

- Mode: Split

- Split ratio: 1:50

- Stop time: 15 min.

Head space parameters

- Incubation temperature: 80°C

- Agitator Speed: 500 rpm

- Incubation Time:20 min

- Agitator on time: 10 sec

- Agitator off time: 10 sec

- Flush Time: 2.0 min

- Syringe temperature: 90 °C

- Pressurization Time: 0.08 min

- Injection Volume: 1000 µL

- Fill speed: 500 µl /sec

- Fill stroke: 1

- Injection speed: 500 µL/sec

- GC Cycle Time :20 min

- Sample preparation: prepare 0.4 % v/v of Ethanol in water.

- Prepare six vials each contains 2 ml test solution. Seal the vial with PTFE septa and cap, place in the headspace analyzer. Run the experiment.

- Retention time for ethanol shall be about 4.0 min.

- Acceptance criteria:

- RSD for peak area should not be more than 5.0 %

- RSD for retention time should not be more than 0.5%

- Record the details in Annexure-II.

- Calibration Schedule: Once in six months and after any major maintenance Job.

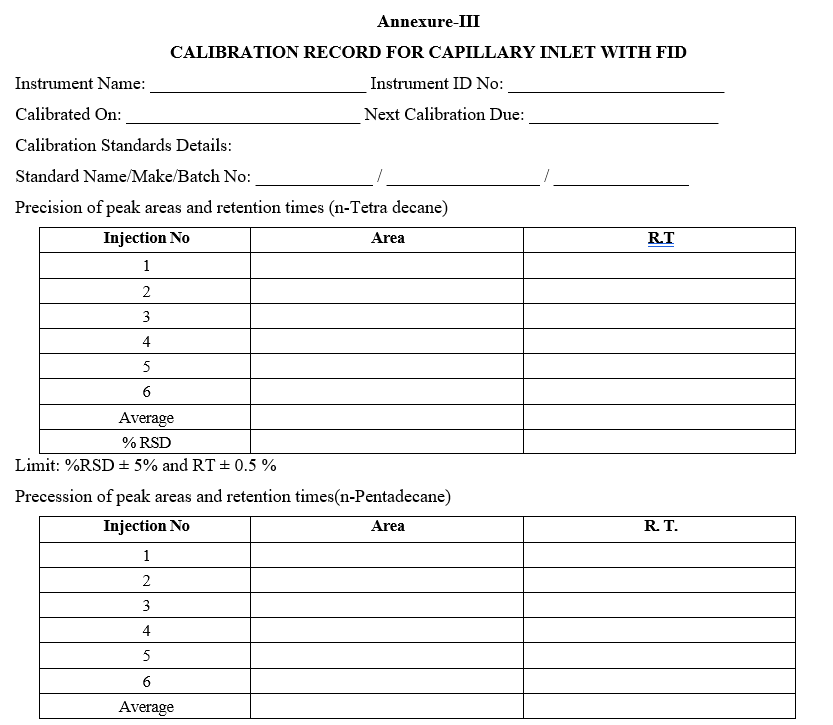

- CALIBRATION OF CAPILLARY INLET WITH FID:

- Fix the column for capillary inlet to FID.

- Chromatographic parameters

- Column: HP –5, 30 mx0.32 mm ID x 0.25µ

- Inlet temperature: 250°C

- Carrier gas: Helium/Nitrogen

- Flow mode: Constant pressure

- Inlet pressure column 25 psi

- Detector Temperature: 300°C

- Injection Volume: 1 µL

- Column Flow: 0.8 ml/min

- Hydrogen Flow: 45 ml/min

- Mode: Split less

- Air Flow: 450 ml/min

- Makeup Flow: 7 ml/min

- Run time: 8.5 min

- Oven temperature Program: Initially held at 60°C then raised to 90°C at 25°C/min. Then again increased to 170°C at 15°C /min. Hold at 170° C for 2 min.

- Procedure: Inject the sample 6 times as per the procedure and calculate the RSD for retention times and peak areas of individual peaks.

- Acceptance criteria:

- RSD for peak area should not be more than 5.0 %

- RSD for retention time should not be more than 0.5%

- The average area of individual peaks should be greater than the value mentioned in the annexure-III.

- Record the details in calibration record in Annexure-3

- Calibration Schedule: Once in six months and after any major maintenance Job.

- CALIBRATION OF DETECTOR LINEARITY FOR FID:

- Chromatographic parameters:

- Column: Fused silica column 30 m long 0.32 m internal diameter with 1.8µ

- Injection temperature 190°C

- Carrier gas: Helium/Nitrogen

- Flow mode: Constant Flow

- Detector Temperature: 250°C

- Hydrogen Flow: 45 ml/min

- Air Flow: 450ml/min.

- Make flow :30ml/min

- Column Flow: 1mL/min

- Mode: Split

- Split ratio: 1:50

- Injection Volume: 1000 µL

- Run time 20 min.

- Oven temperature Program: Initially held at 70 °C for 10 min. Then raised to 260°C at 70°C/min and Hold at 260° C for 5 min.

Head space parameters

- Incubation temperature: 120°C

- Agitator Speed : 500 rpm

- Incubation Time:30 min

- Agitator on time : 10 sec

- Agitator off time: 10 sec

- Flush Time : 2.0 min

- Syringe temperature : 130 °C

- Pressurization Time: 0.08 min

- Injection Volume :1000 µL

- Fill speed : 500 µl /sec . Fill stroke: 1

- Injection speed: 500 µL/sec .

- GC Cycle Time: 25 min

Preparation IPA stock solution :

- Take 500µl of IPA into a 25ml flask having about 20 ml of NN-DMF and then dilute it to volume with NN-DMF and mix well.

Preparation of solutions for Linearity.

| S. No | Volume of STD stock (ml) | Dilute to 10 ml of NN- DMF | |

| 01 | 1 | 10 | |

| 02 | 2 | 10 | |

| 03 | 3 | 10 | |

| 04 | 4 | 10 | |

| 05 | 5 | 10 | |

| 06 | 6 | 10 | |

- Pipette 5 ml of each solution into individual vials. Fit them with a septum and crimp cap and then seal it and inject.

- Calculate the coefficient of correlation.

- Acceptance criteria: Coefficient of correlation NLT 0.99.

- Calibration: Once in six months and after any major maintenance Job.

- Record the Details in annexure-IV.

CALIBRATION OF COLUMN OVEN TEMPERATURE TEST:

- Set the oven temperature to 35°C and wait for at least 5 min to stabilize the oven, take the temperature reading from the data logger and record the temperature.

- Set the oven temperature to 100 °C and wait for at least 5 min, after the oven gets Stabilized record the data logger reading in the annexure.

- Set the oven temperature to 230 °C and wait for at least 5 min, after the oven gets Stabilized record the data logger reading in the annexure.

- Acceptance criteria:

- The difference at 35°C should not be more than 2°C from the set value.

- The difference at 100°C should not be more than 4°C from the set value.

- The difference at 230° C should not be more than 5°C from the set value.

- Record the details in Annexure-V.

- Calibration schedule: Once in six months and after any major maintenance Job

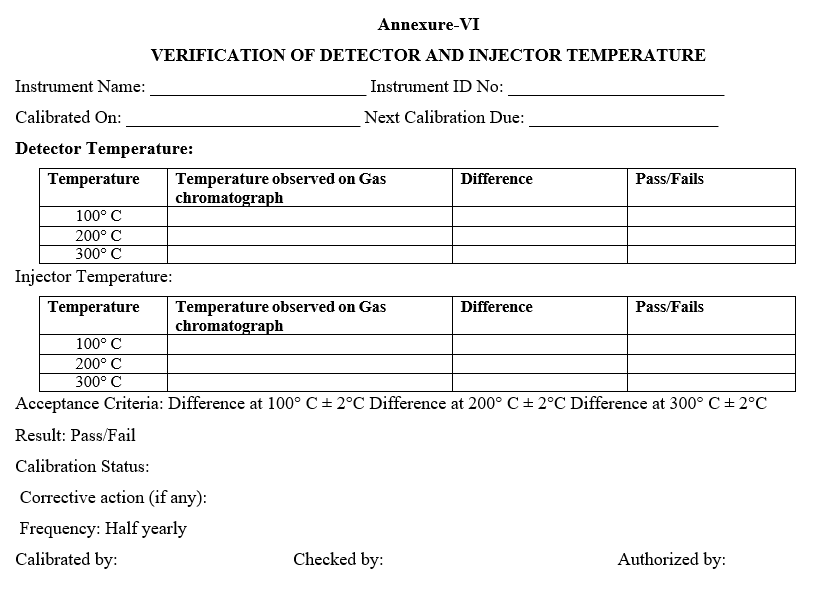

- VERIFICATION OF DETECTOR AND INJECTOR TEMPERATURE:

- Detector:

- Set the detector temperature to 100°C and wait for at least 15 min and record the Temperature in Annexure -VI.

- Repeat the above step for remaining temperatures 200°C and 300°C.

- Injector:

- Set the injector temperature to 100°C and wait for at least 15 min and record the temperature in Annexure-VI.

- Repeat the above step for remaining temperatures 200°C and 300°C.

- Acceptance criteria:

- The difference at 100°C should not be more than 2°C from the set value.

- The difference at 200°C should not be more than 2°C from the set value.

- The difference at 300°C should not be more than 2°C from the set value.

- Calibration schedule: Once in six months and after any major maintenance Job.

- ANNEXURES:

| ANNEXURE NO. | TITLE OF ANNEXURE |

| Annexure-I | Calibration record of Flow accuracy |

| Annexure-II | Calibration record for Headspace sampler With FID |

| Annexure-III | Calibration record for capillary inlet with FID |

| Annexure-IV | Calibration record of Detector Linearity for FID |

| Annexure-V | Calibration record of Column oven temperature Test |

| Annexure-VI | Verification of Detector and Injector temperature |

Annexure-I

CALIBRATION RECORD OF FLOW ACCURACY

Annexure-II

CALIBRATION RECORD FOR HEADSPACE SAMPLER WITH FID

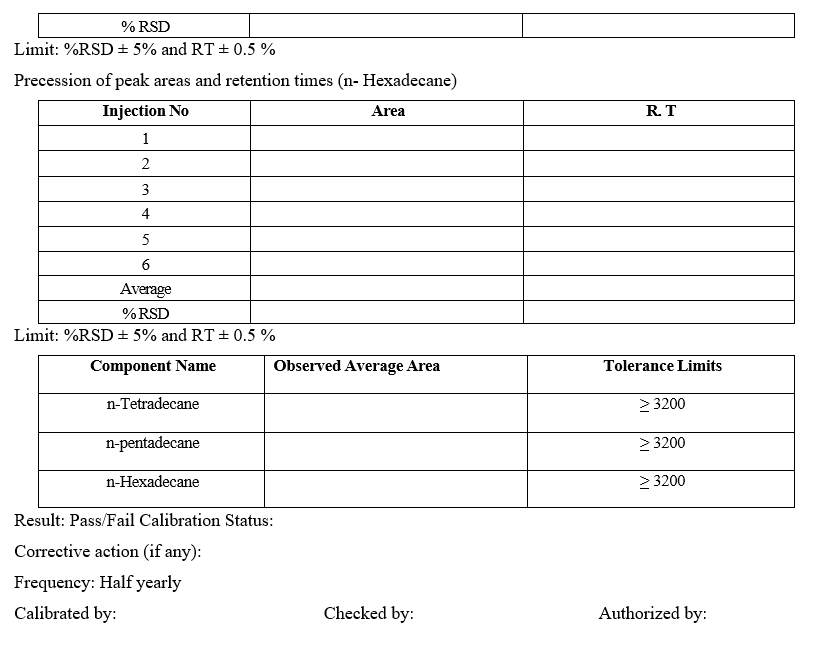

Annexure-III

CALIBRATION RECORD FOR CAPILLARY INLET WITH FID

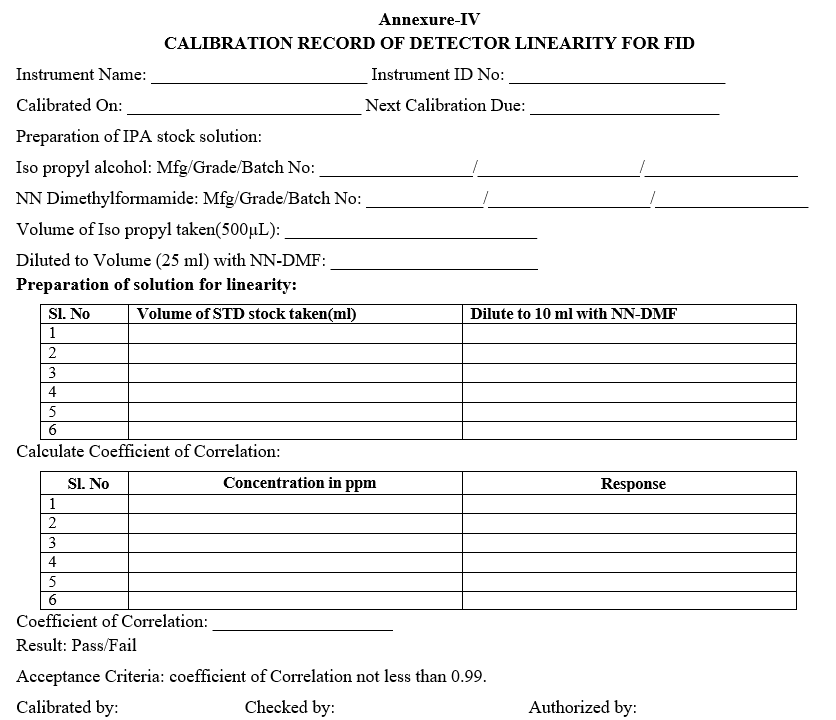

Annexure-IV

CALIBRATION RECORD OF DETECTOR LINEARITY FOR FID

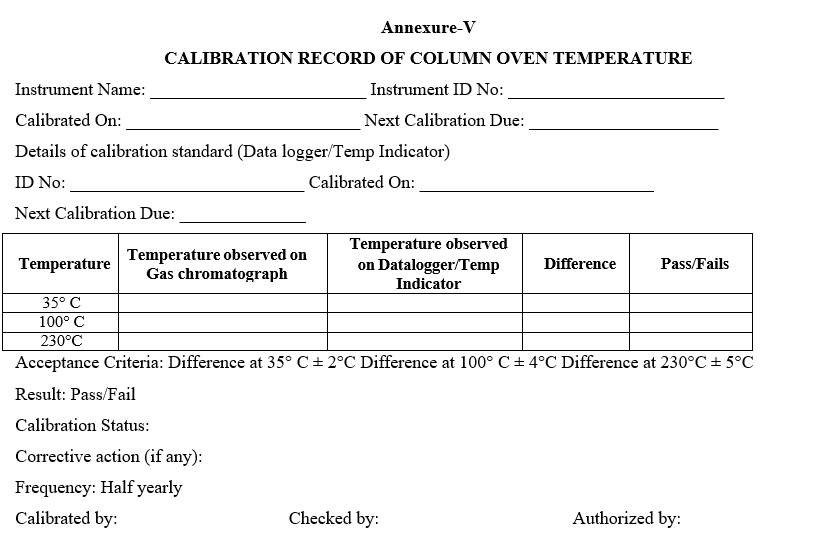

Annexure-V

CALIBRATION RECORD OF COLUMN OVEN TEMPERATURE

Annexure-VI

VERIFICATION OF DETECTOR AND INJECTOR TEMPERATURE