- OPERATING PROCEDURE OF HPHV STEAM STERILIZER:

- Make – Pharma lab

- OPERATION OF AUTOCLAVE:

- The Steam Sterilizer shall be used for sterilization of glassware’s, garments and stainless steel items and culture media.

- Use purified water in steam generator to avoid the scale formation.

- Open the Compressed air valve, Ensure the Compressed air pressure is 6-7 kg/cm2 on the pressure regulator.

- This autoclave contains four types of activities (Cycles).

- Vacuum leak test.

- Bowie-dick test.

- Standard process.

- HPHV process.

- Control panel:

- Panel: – Red colour rotating switch present on the control panel use to switch on the mains.

- Red colour rotating switch present inside the control panel, Turn to “1” position indicates running in AUTO mode, turns to “2” position indicates running in MANUAL mode and position turn to “0” position indicates “OFF” position. (Always run the control panel in AUTO mode).

- Control panel contains MMI (PLC display) and YOKOGAWA data logger to record the results.

- Results displayed on MMI recording through dot matrix printer and from YOKOGOWA data logger results should be down load to Computer through the chip.

- “EMERGENCY SWITCH” present on the control panel to stop the process in emergency.

- Turn on the “Heaters ON” “Feed pump ON” switch to start the heating of the water in steam generator to generate the steam.

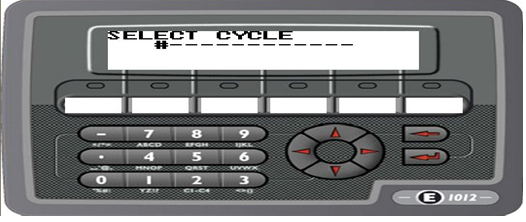

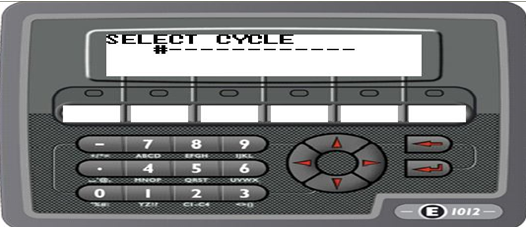

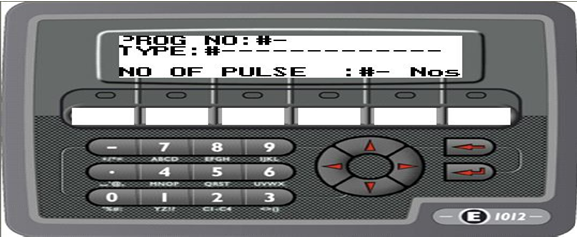

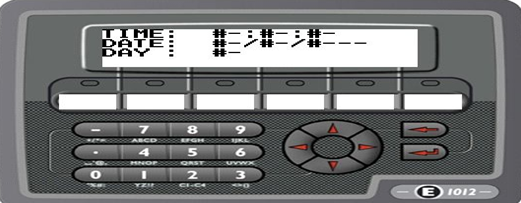

- The below screen is the basic front view of HMI E-1012 which has mainly SIX number of function key which we can define as F1, F2, F3, F4, F5, and F6. Each key has its own alarm light above the key.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-hphv-steam-sterilizer/

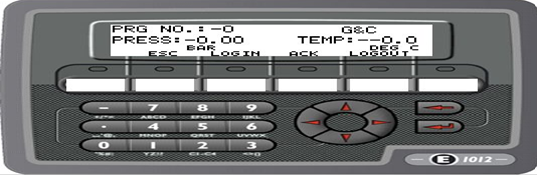

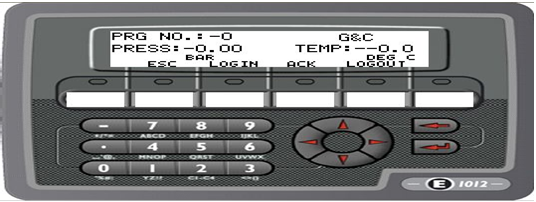

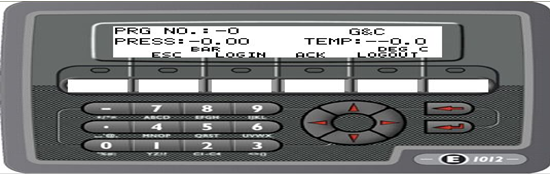

- During healthy condition of system the below ANALOG SCREEN shall be displayed.

- Press F1 function key for go to Analog Screen.

- Press F2 for Esc from this current display.

- Press F3 function key for login.

- Press F4 function key for Acknowledge the alarm. During alarm condition F4 light will blink Red.

- Press F5 function key for Logout from current operating level.

- Press F1 key and go in Analog Screen as seen below, scroll the screen by UP & DOWN arrow key to see different analog temperature.

- Press F2 key to escape and return to main screen and display the below screen

- LOGIN PROCESS

- Press F3 key and in Screen as seen below:

- After come in this display Press F2 for login and HMI will ask for password, Give appropriate password level for Login, and then press enter and display the above screen.

- Press F3 to start cycle which is loaded as per recipe.

- Press F4 to go back from this current screen.

- Press F5 to edit the current recipe.

- FOR EDIT CYCLE SET PARAMETER

- Press F5 in screen as displayed and see the below screen and then press F5 button for (OK Button ) for edit the set parameters.

- Press F3 for save the changes parameters, and then press enter button and the below main screen will display.

- Select the Cycle Number like 1, 2, 3 & 4 and press ENTER button and go in below screen.

- Cycle Number 4.1.5.18.2

- is Vacuum leak test

- is Bowie-dick test.

- is Standard process.

- is HPHV process.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-hphv-steam-sterilizer/

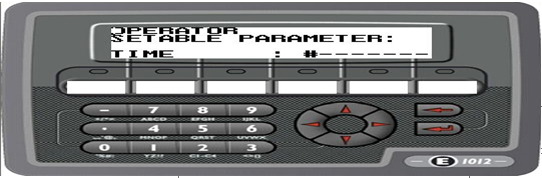

- FOR EDIT CYCLE SET PARAMETER

- Press F3 for Login and display the below screen

- Press F3 for escape and display the main screen.

- Press F5 for edit the set parameters and press OK and edit the set parameters.

- In this screen, change the parameters as per requirement (in case of Standard cycle-1 and 2) and scroll the Screen by pressing UP & DOWN arrow key.

- Press F3 for save the changed set parameters and then press and display the below main screen.

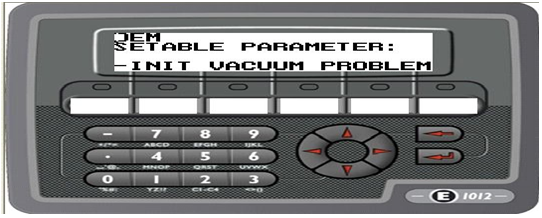

- FOR EDIT OEM SET PARAMETER:

- Press F2 key two times for edit the OEM set parameters and the below screen shall be displayed.

- If any changes are required, press UP & DOWN arrow keys for change the set parameters, and then press arrow and then press enter and return to the main screen

- Now Press F4 and go in OEM Parameter Screen as shown below where can be edit the Parameter as per requirement.

- FOR EDIT BATCH DATA, EQUIPMENT ID, CYCLE No. OPERATOR NAME and DATE & TIME:

- Press F2 key two times and display the below screen:

Press F5 for edit or change the Batch data, Equipment ID, Cycle Number, Operator Name and Date & Time and display the below screen

- Press F1 and enter the password and change the parameters and press Enter button.

- Press F3 button for return to the OEM set parameters and display the below screen.

- Press the arrow key and then press Enter key and display the below main screen.

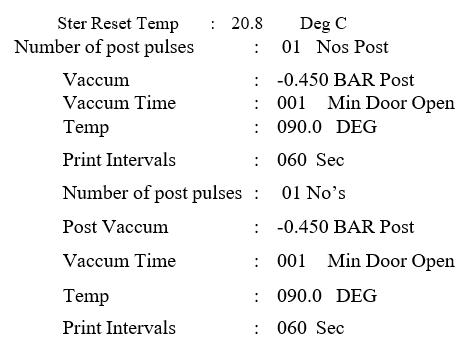

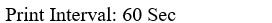

- Cycle set parameters: Vacuum leak test set parameters:

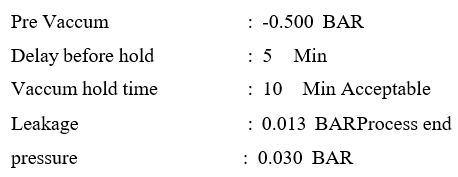

- Vacuum leak test set parameters:

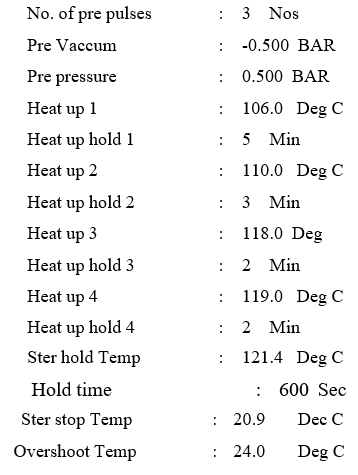

- Bowie dick test set parameters

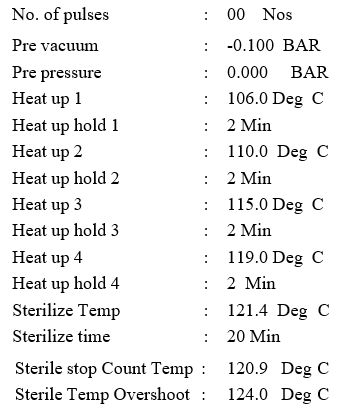

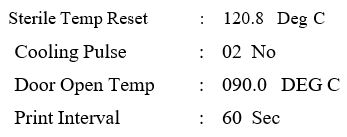

Standard process set parameters – 1

Standard process set parameters – 2

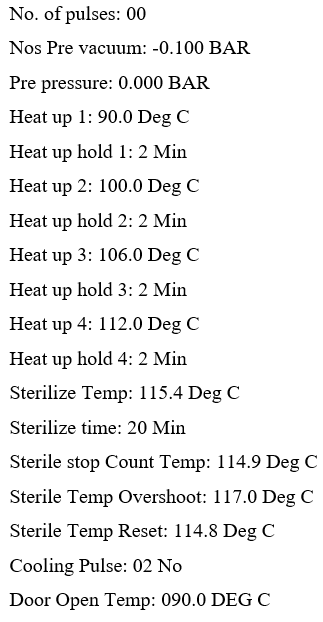

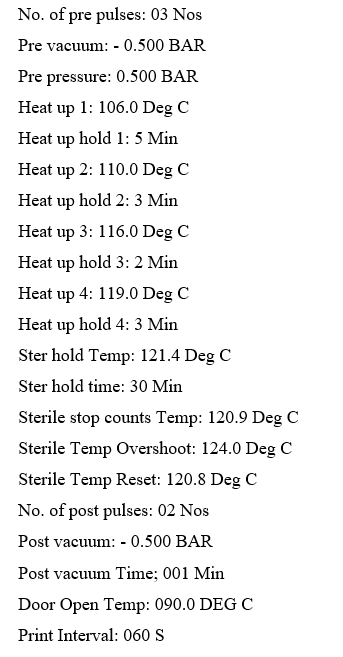

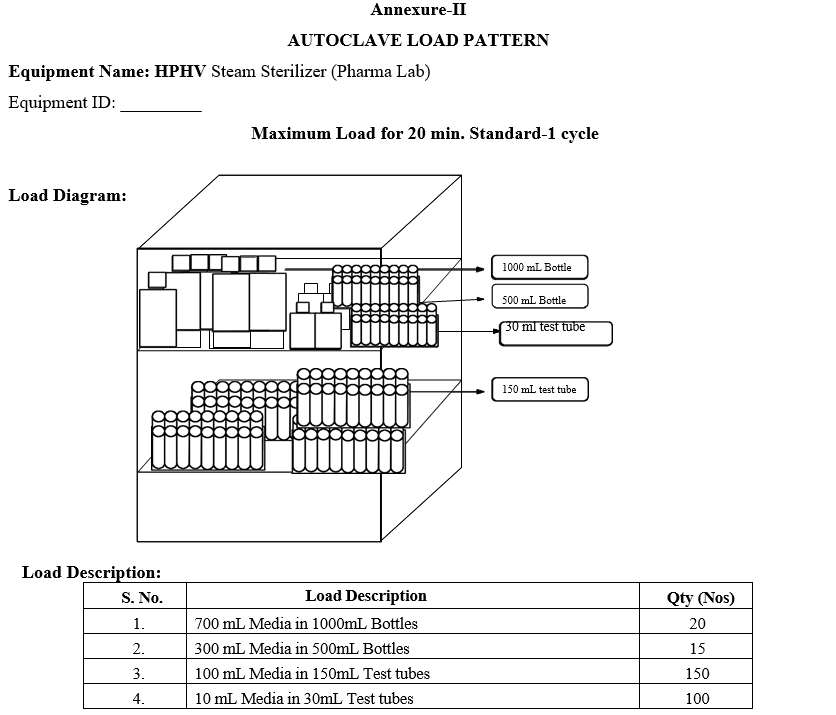

- HPHV PROCESS set parameters

- Keep all the items to be loaded into the autoclave as per the load pattern and press “PUSH DOOR 1 CLOSE BUTTON” by manually to close the door.

- Select the cycle Number as per requirement by Press “1, 2, 3 & 4”numbers on HMI will display the cycle name. Press “SET PARAMETERS” and set the validated parameters stated above and select required process and press F2 button provided on the HMI, display will ask the cycle START/STOP.

- Press “YES BUTTON” cycle will start.

- NOTE: – The machine shall be operated in “MANUAL MODE” when the “AUTO MODE” is not working.

- PROCEDUREFOR MANUAL MODE OPERATION:

- The machine shall be operated from the toggle switches provided inside the control panel. Switch on the mains.

- Rotate the switch 2 position for MANUAL MODE Switch on “MANUAL MODE”.

- Switch on “JKT STEAM”, “CHAM STEAM” and “CHAM BY PASS VALVE”.

- When the temperature reaches 121°C, then wait for the stipulated hold time.

- After the hold time is completed, put off “CHAMBER STEAM”, “JKT STEAM” and switch on “AIR VENTING VALVE”.

- When the temperature comes down to 90°C open the door by pushing “DOOR -2 OPEN”.

- UNLOADING

- After satisfactory completion of sterilization, sterile side door only will open.

- Open the door by pushing “DOOR-2 OPEN” switch.

- Wait for some time the door will open, unload the required items at sterile side.

- Close the door by pushing “DOOR-2 CLOSE” switch.

- STERILIZATION HOLD TIMINGS

- Standard process – 121°C – 20 minutes.

- HPHV process– 121°C – 30 minutes.

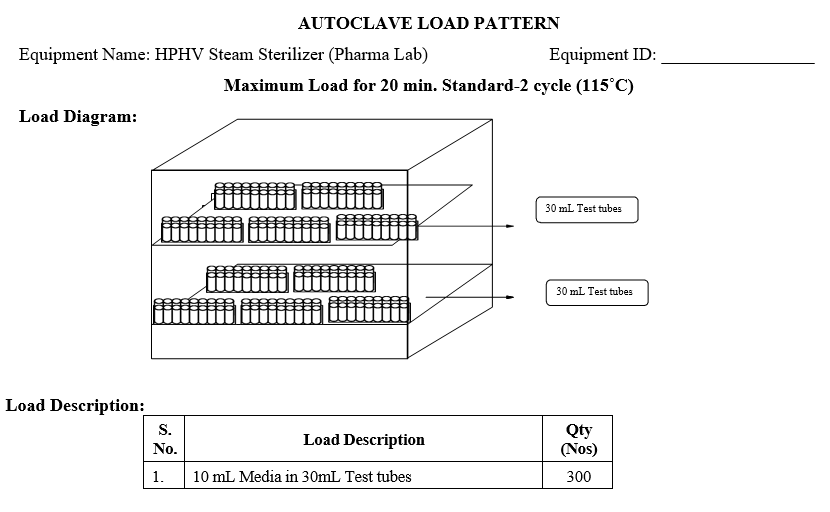

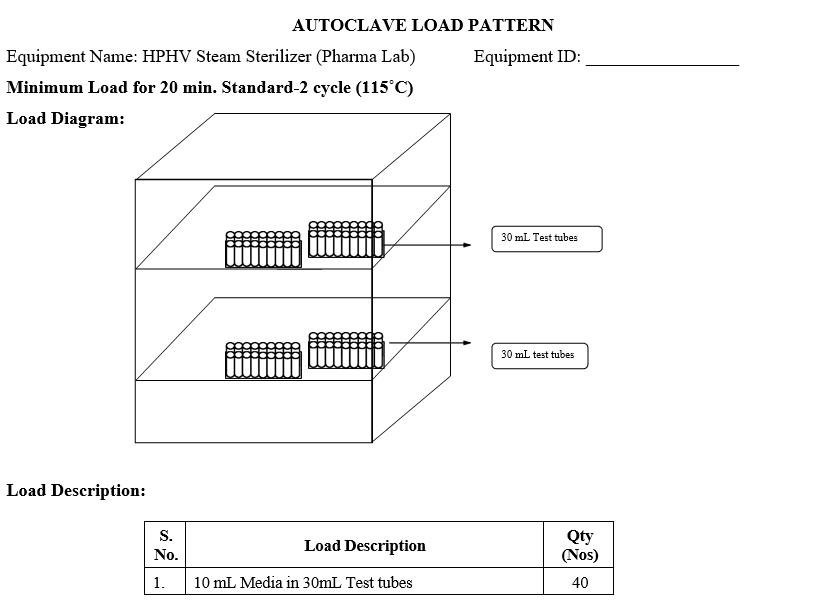

- Standard process – 115°C – 20 minutes.

- Vacuum leak test – Vacuum hold-10 minutes & Bowie-Dick test – 121°C – 600 sec (10 min).

- Record the temperature, time and load details for each cycle in “Autoclave Usage Log Record”.

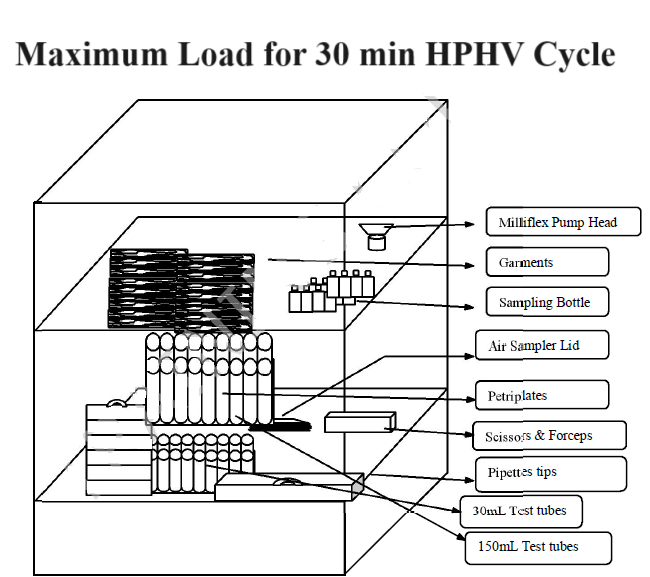

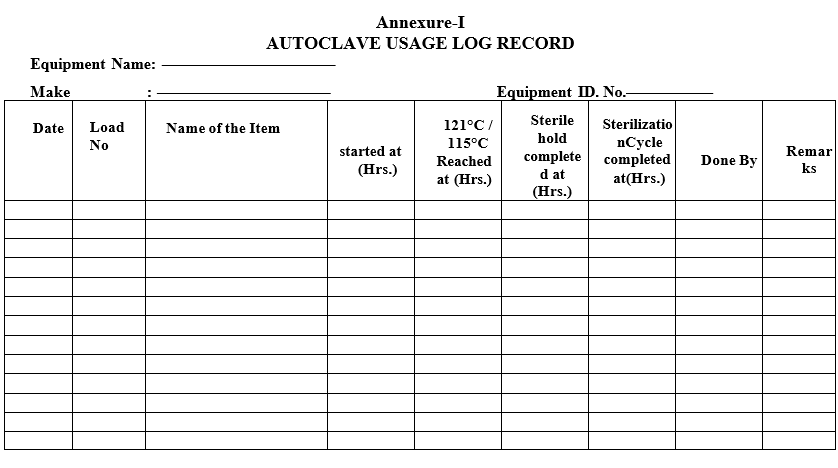

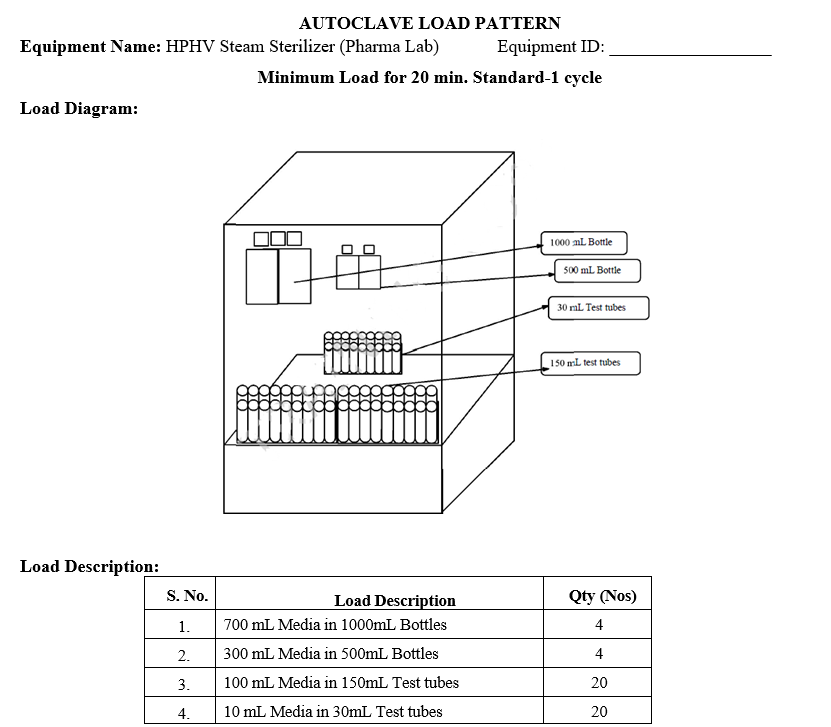

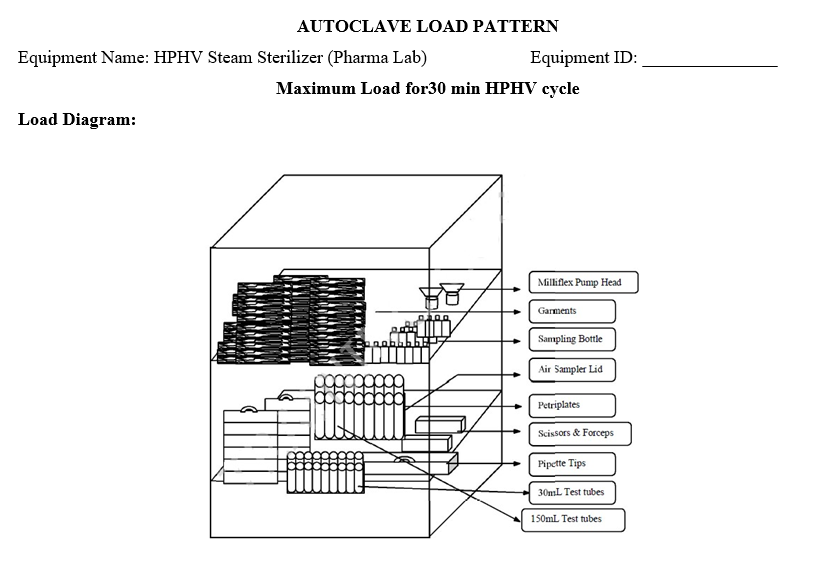

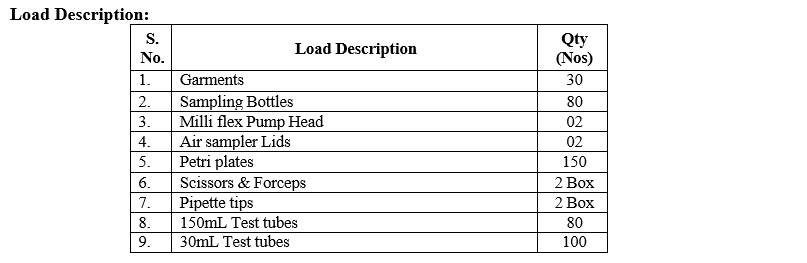

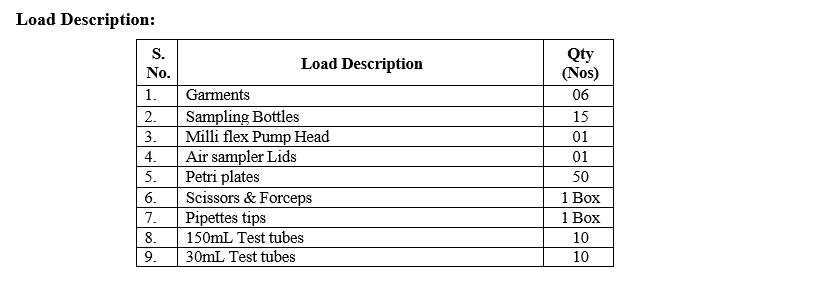

- Load the articles to be sterilized as per the Diagrammatic representation in Format-II.

Assigning of Load numbers:

For autoclave loads write as follows

- For HPHV process AH250001,

where

“AH” indicates the HPHV process,

“25” indicates the year and

“0001” Indicates the load number 1 and the sequence follows for the next cycle.

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-hphv-steam-sterilizer/

- For “STANDARD PROCESS” process AS250001,

Where

“AS” indicates the standard process,

“25” indicates the year and “0001” Indicates the load number 1 and the sequence follows for the next cycle.

- For “Bowie DICK TEST” process AB250001,

Where

“AB” indicates the Bowie Dick test,

“25” indicates the year and

“0001” Indicates the load number 1, and the sequence

follows for the next cycle. This test can be performed once in a month with a grace period of 3 days.

- For “VACCUM LEAK TEST” process AL250001,

Where

“AL” indicates the Vacuum leak test,

“25” indicates the year and

“0001” Indicates the load number 1 and the sequence follows for the next cycle.

Daily once can be done before the sterilization cycles.

- DISCRIPENCIES DURING AUTOCLAVE OPERTAION: Any discrepancies observed during autoclave operation against set parameters raise PNC /Incident as per SOP.

- ANNEXURES:

| Annexure No. | Title of annexure |

| Annexure-I | Autoclave Usage Log Record |

| Annexure-II | Autoclave Load pattern |

- ABBREVIATIONS:

| No. | : | Number |

| MMI | : | Man Machine Interface |

| HMI | : | Human Machine Interface |

| Deg. | : | Degree |

| HPHV | : | High Vacuum High Pressure |

| Kg | : | Kilo gram |

| cm | : | Centimeter |

| PNC | : | Process Non conformance |

| PLC | : | Programmable logic controller |

| SOP | : | Standard Operating Procedure |

| QC | : | Quality Control |

Annexure-I

AUTOCLAVE USAGE LOG RECORD

Annexure-II

AUTOCLAVE LOAD PATTERN

Click the link for download word file copy of this document:

https://pharmaguidehub.com/product/operation-of-hphv-steam-sterilizer/