- OBJECTIVE:

To lay down a procedure for AHU Parameter monitoring.

- SCOPE:

This SOP is applicable for AHU Parameter monitoring at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible to perform the activity as per the SOP.

- Manager / Executive – Engineering shall ensure compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Switch ON the AHU as per the respective SOP.

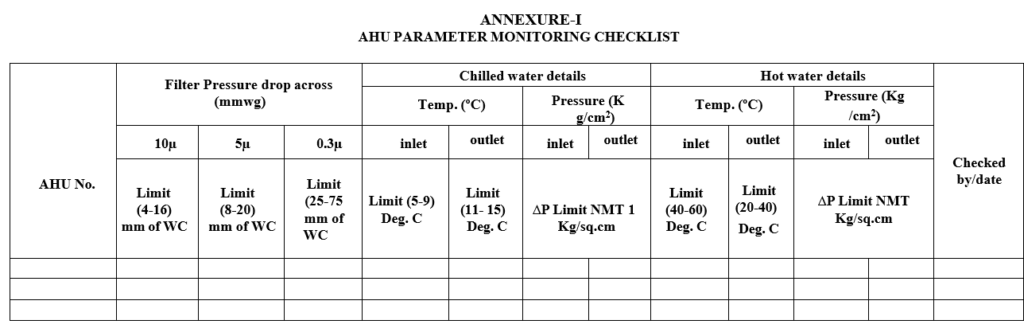

- Measure the differential pressure across the filters (10, 5 & 0.3 microns) by using Calibrated digital manometer or magnehelic gauge.

- Whenever differential pressure of filters exceeds the specified alert limits, clean the filter as per the SOP

- After cleaning the filters ensure that clean filters differential pressure is within the limits and enter filter cleaning details in ‘Filter cleaning log’.

- Check the chilled water/hot water inlet and outlet pressure and check the functioning of modulating valves.

- If the inlet and outlet pressure difference is more than 1 kg/cm2, clean the strainer.

- Check the chilled water/hot water inlet and outlet temperature.

- Chilled water inlet temperature should be in the range of 5 – 9°C and outlet temperature should be in the range of 11 – 15°C. Hot water inlet temperature should be in the range of 40 – 60°C and outlet temperature should be in the range of 20 – 40°C.

- AHU Parameters shall be checked once in 15±3 days for all process areas and 30 ±1 day for all other Non process areas, and recorded in Annexure-I.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/ahu-parameter-monitoring/

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | AHU Parameter Monitoring checklist |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

SOP : Standard Operating Procedure

kg/cm2 : Kilograms per square centimeters

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

AHU PARAMETER MONITORING CHECKLIST

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/ahu-parameter-monitoring/