- OBJECTIVE:

To lay down a procedure for chemical preparation of the Sodium hypochlorite, SMBS, Anti scalent & Sodium Hydroxide solutions.

- SCOPE:

This SOP is applicable for chemical preparation of the Sodium hypochlorite, SMBS, Anti scalent & Sodium Hydroxide solutions at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible for follow the procedure.

- Executive– Engineering is responsible to ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

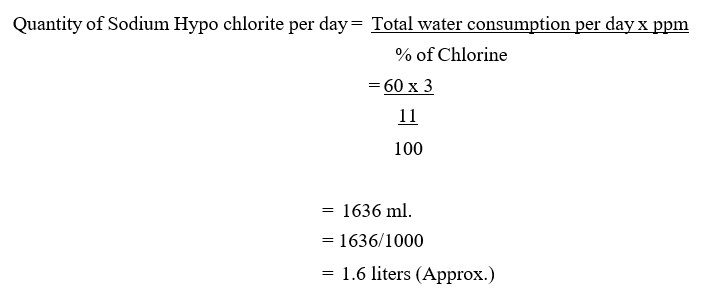

- CONSUMPTION OF SODIUM HYPO CHLORITE SOLUTION PER DAY:

Total consumption of water per day = Flow rate (m3 /hr) x working hours

For e.g. Hypo chlorite dosing for 3 PPM

Total consumption of water per day = Flow rate (m3 /hr) x working hours

= 2.5 x 24

= 60 KL (Approx.) Required

Hypo chlorite dosing = 3 ppm

Available Hypo chlorite dosing = 11 % ( w/v chlorine)

- PREPARATION OF SODIUM HYPOCHLORITE SOLUTION.

- Take 1.6 liters of Sodium Hypo chlorite having 11% w/v of chlorine in dosing tank and add 50 liters of purified water and mix it properly by SS rod.

- The dosing pump also interlocked with raw water tank and each time it shall be pumped 1.2 liters of solution. Dosing pump put in 1.2 Lts/ hr by adjusting the fine tuning the knob.

- Prepare the solution one time for 24 hours. Use freshly prepared solution every day.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preparation-of-sodium-hypochlorite-smbs-antiscalent-and-sodium-hydroxide-solutions/

- PREPARATION OF SMBS SOLUTION:

- Chemical calculation:

For e.g. SMBS dosing for

Flow rate per hour = 2.0 m3/hr

Running hours per day = 24 Hours

Required SMBS dosing = 6 ppm

Quantity of SMBS per day = Flow rate (m3/hr) x ppm x 24

= 2.0 x 6 x 24

= 288 grams

= 300 grams (Approx.)

- Take 300 grams of SMBS powder in the dosing tank and add 50 liters of purified water and dissolve it completely by SS rod.

- Ensure that 24 hours of working and dosing 1.2 liters per hour by adjusting the dosing pump provided for tuning the knob.

- Prepare the solution one time for 24 hours. Use freshly prepared solution every day.

- PREPARATION OF ANTI SCALENT SOLUTION:

- Chemical calculation:

For e.g. if Antiscalent dosing for 5 ppm

Flow rate per hour = 2.0 m3/hr

Running hours per day = 24 Hours Required Antiscalent dosing = 5 ppm

Quantity of Antiscalent per day = Flow rate (m3/hr) x ppm x 24

= 2.0 x 5 x 24

= 240 grams.

= 250 (Approx.)

- Take 250 grams of Antiscalent in the dosing tank and add 50 liters of purified water and mix it properly by SS rod.

- Ensure that 24 hours of working and dosing 1.2 liters per hour by adjusting the dosing pump provided for tuning the knob.

- Prepare the solution one time for 24 hours. Use always freshly prepared solution every day.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preparation-of-sodium-hypochlorite-smbs-antiscalent-and-sodium-hydroxide-solutions/

- PREPARATION OF NAOH SOLUTION FOR pH CORRECTION

- Chemical calculation:

For e.g.

Quantity of NaOH per day = Flow rate (m3/hr) x ppm x 24

= 2.2 x 6 x 24

= 316 grams

= 350 (Approx.)

- Take 350 grams of NAOH in the dosing tank and add 50 liters of water of purified water and mix it properly by SS rod.

- Ensure the 24 hours of working and dosing 6.3 liters per hour by adjusting the dosing pump provided for tuning the knob.

- Prepare the solution one time for 24 hours. Use freshly prepared solution every day.

- PREPARATION OF NAOH SOLUTION FOR pH CORRECTION UV OUTLET

- Chemical calculation:

For e.g.

Quantity of NaOH per day = Flow rate (m3/hr) x ppm x 24

= 0.73 x 6 x 24

= 105 grams

= 100 grams. (Approx.)

- Take 100 grams of NAOH in the dosing tank and add 50 liters of water of purified water and mix it properly by SS rod.

- Ensure the 24 hours of working and dosing 1.2 liters per hour by adjusting the dosing pump provided for tuning the knob.

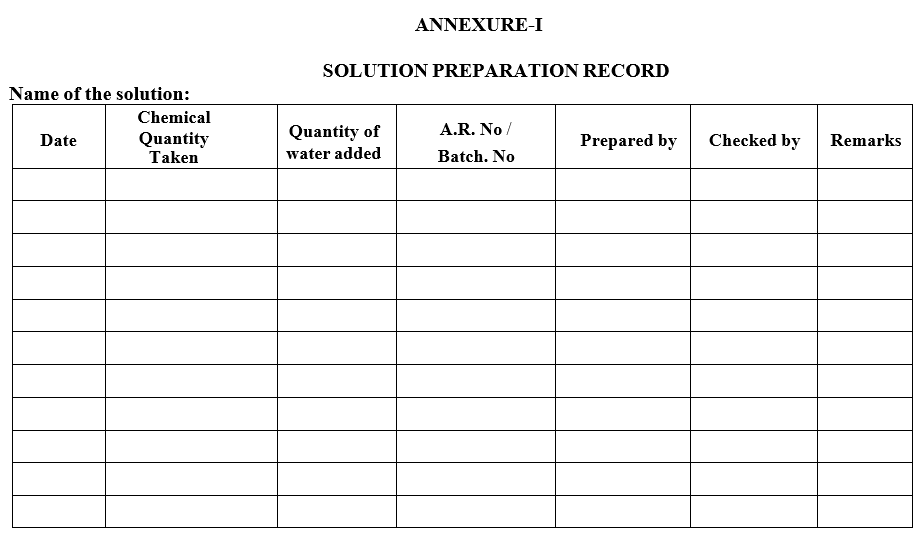

- Prepare the solution one time for 24 hours. Use freshly prepared solution every day. Record the solution details as per Annexure-I.

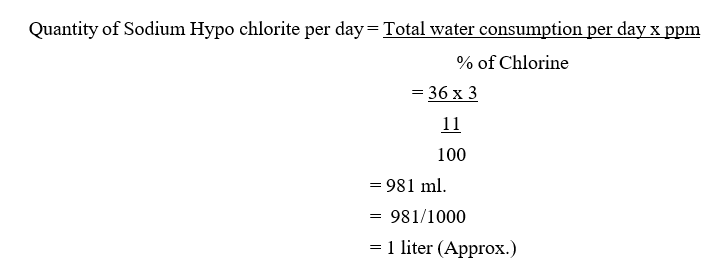

- PREPARATION OF SODIUM HYPO CHLORITE SOLUTION (FOR UF PERMEATE TANK)

- Chemical calculation:

For e.g.

Total consumption of water per day = Flow rate (m3 /hr) x working hours

= 1.5 x 24

= 36 KL (Approx.) Required Hypo chlorite dosing = 3 ppm

Available Hypo chlorite dosing = 11 %( w/v chlorine)

- Take 1 liter of Sodium Hypo chlorite having 11% w/v of chlorine in dosing tank and add 50 liters of purified water and mix it properly by SS rod.

- The dosing pump also interlocked to the RO-I product water recirculation line to Pre UF permeate tank and each time it shall be pumped 1.2 liters of solution.

- Prepare the solution one time for 24 hours. Use freshly prepared solution every day. Record the solution details as per Annexure –I.

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preparation-of-sodium-hypochlorite-smbs-antiscalent-and-sodium-hydroxide-solutions/

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Solution Preparation Record. |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

PPM : Parts per million

SMBS : Sodium meta bi Sulphite

NaOH : Sodium hydroxide

KL : Kilo liter

SS : Stainless Steel

NaOCl : Sodium Hypochlorite

w/v : Weight / Volume

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

SOLUTION PREPARATION RECORD

Click the link to download word file copy of this document:

https://pharmaguidehub.com/product/preparation-of-sodium-hypochlorite-smbs-antiscalent-and-sodium-hydroxide-solutions/