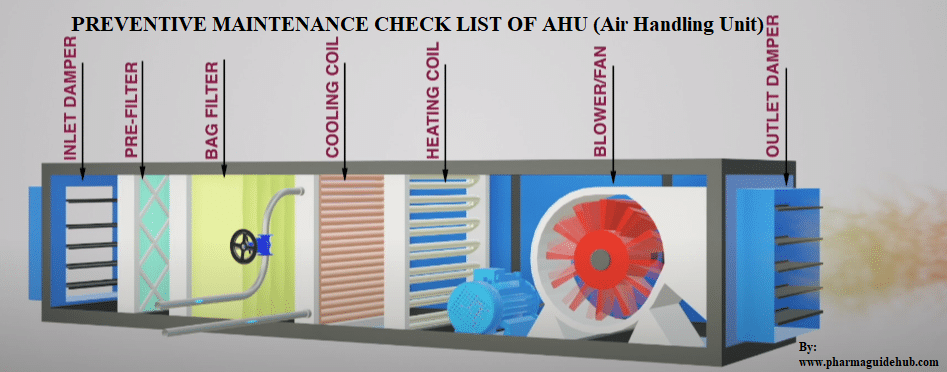

Preventive maintenance of an Air Handling Unit (AHU) involves regular checks and tasks to ensure efficient operation, prevent breakdowns, and prolong its lifespan. Here’s a comprehensive checklist:

| Department : Engineering Equipment Name :Air Handling Unit Equip. No./ID: Frequency: Quarterly | |||||

| S. No | Check Points | Procedure | Activity | Done By / Date | |

| 01 | Check the Motor and Blower pulleys alignment. | With the help of thread facing on the pulley face check the alignment of motor pulley and blower pulley if any clearance noticed adjust the pulleys equally in line. If pulleys observed damage then replace the same. | |||

| 02 | Check motor & blower base bolts for tightness. | Take the exact spanner of that specific bolt and nut for tighten the bolts. | |||

| 03 | Check the condition of motor bearings and blower shaft bearings. | Physically observe for any abnormal sound and also observe the motor end covers for hot. If observed any of these abnormalities bearings shall be replaced. | |||

| 04 | Check the V-belt condition. | Check the V belt tension by pressing the belts together if found tight or elongation adjust the adjustable nuts on the motor base accordingly. If physical condition of the V-belt found brittle replace the belt. | |||

| 05 | Check the chilled water line inlet and outlet valves. | By operate the valve handles to and fro, if found leakages service the valves or replace. | |||

| 06 | Check the Hot water line inlet and outlet valves. | By operate the valve handles to and fro, if found leakages service the valves or replace. | |||

| 07 | Check the condition of cooling coil & Heating coil. | By Physical verification of the coils if found any leakage the same shall be repaired or replace. | |||

| 08 | Check the door gaskets. | By Physical verification of the door gasket found worn out replace the same. | |||

| 09 | Check the condition of the filter. | By both the physical verification and verifying the differential pressures across the filter. If found filter chock clean with compressed air afterwards with water and dry in the drier. If still the differential pressure s are not within the limit, replace the filters. | |||

| 10 | Check the DP of Chilled water & Hot water pressure. | By verifying the differential pressure across the inlet and outlet of chilled and hot water lines and the differential pressure is more than 1Kg/cm² clean the strainer. | |||

| 11 | Check the Cooling & Heating Coil and Clean the coil fins if required. | By Physically verifying the cooling and heating coil fins and found dust/powder accumulation clean the fins with Aluminium brighter from bottom to top horizontally and rinse with water from top to bottom vertically. | |||

| 12 | Check the performance of coil. | After cleaning the strainer also still found differential pressure is more than 1Kg/cm²between the inlet and outlet of the chilled and hot water lines .De-scaling of the coil shall be done by circulating the De-scaling chemical. | |||

| 13 | Check the cooling coil condensate tray. | By Physical verification of the cooling coil condensate tray and found tidy clean with cloth and if require clean with 40% Sodium Hypochlorite solution. | |||

| 14 | Ensure the earthing of motor. | Check the earthing wires for proper connection. | |||

| 15 | Check & tighten the motor terminals, control wiring terminals, indication lamps and OLR setting | Physical verification and loosen wires shall be tightened with tester. | |||

| 16 | Check the Motor Voltage and Amperage. | By using a Clamp meter ensure that they are within the acceptable Limit with respect to motor rating. | |||

| 17 | Tighten the all control & Communication cable connections in DDC panel. | Physical verification and loosen wires shall be tightened with tester. | |||

| 18 | Check DDC Controller boards & control relays in DDC panel. | By Physical verification ensure proper fixing of DDC controller boards and control relays in DDC panel. If found damage the same shall be replaced. | |||

| 19 | Clean the DDC panel | Clean with Vacuum cleaner and ensure that the panel is cleaned thoroughly. | |||

| 20 | Check the proper functioning of Chilled water & Hot water actuator. | By varying the actuator input values and if not working properly the actuator is removed and serviced. | |||

| 21 | Check the field instrument control cable connections. | Tighten all the field instrument control cable connections with the tester. | |||

| 22 | Ensure proper functioning of the Differential Pressure Switches. | Removing one of the Sensing tube from the Differential pressure switches and observe the continuity of the Differential pressure switch with multi meter. if continuity is not there then filter has to be cleaned with compressed air afterwards with water and dry in the drier. | |||

| 23 | Ensure the proper function of duct smoke detector. | Generate smoke at the smoke detector by removing the glass, the smoke detector senses and AHU motor will be turned OFF. If smoke detector does not sense then the smoke detector should be cleaned. | |||

| Remarks: | |||||

| Checked By / Date | |||||

Additional Tips:

Train personnel: Ensure maintenance personnel are trained to perform tasks correctly and safely.

Maintain accurate records: Keep a record of maintenance activities to track the AHU’s performance and plan future maintenance.

Follow manufacturer’s instructions: Consult the manufacturer’s recommendations for specific maintenance tasks and schedules.

provided a truly healing experience.