- PROCEDURE:

- Dosing pumps shall be calibrated by measuring the output quantity of solution in particular time at different % of flow shown on the pump.

- Before starting the calibration, keep ready calibrated timer and measuring cylinder.

- Stop the Pre-treatment, RO-I and UV-I system before starting of the calibration of the pumps.

- Stop the Dosing pump by operating the Switch ON/OFF and labelled as under calibration.

- Disconnect the discharge pipe from the Service line.

- Set the % of flow at 100 and start the dosing pump by operating the Switch ON/OFF.

- Start the timer and kept the discharge in measuring cylinder.

- After 10 minutes stop the pump and record the result. Accordingly calculate the capacity for 1 hour. This shall be considered as 100 % capacity of the pump.

- Perform the calibration at 25%, 50% and 75% of flow and compare the results with the specifications according to the % of flow.

- If the results are within the limit of ± 5 %, the pump can be used for the operation.

- If the results are out of limit, the diaphragm of the pump shall be changed, and calibration is performed.

- Even though after changing the diaphragm, if it is not performing, the pump shall be changed, and calibration performed.

- After calibration completion it is labelled as calibrated. If it fails, labelled as calibration Failed.

- Switch ON the dosing pumps and start the Pre-treatment, RO-I and UV-I system.

- The calibration of dosing pumps shall be performed for quarterly along with the Quarterly preventive maintenance of purified water system.

- The grace period is followed as per the SOP.

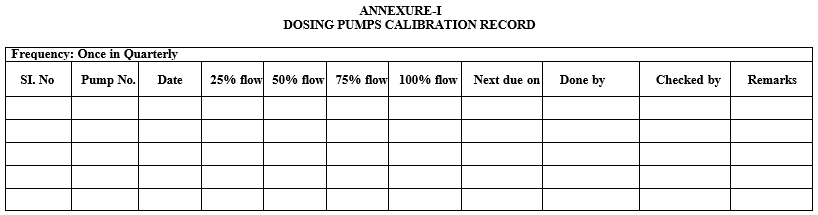

- Record the dosing pumps calibration details as per Annexure-I.

- REFERENCES:

- Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Dosing pumps Calibration Record |

- ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

- RO : Reverse Osmosis

- UF : Ultra Filtration

- NaOcl : Sodium hypochlorite

- SMBS : Sodium Meta bi Sulphite

- NaOH : Sodium hydroxide

- SOP : Standard Operating Procedure

- QA : Quality Assurance

- REVISION HISTORY:

- CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

Annexure-I

DOSING PUMPS CALIBRATION RECORD