- OBJECTIVE:

To lay down operating procedure of Air compressor and Air dryer.

- SCOPE:

This SOP is applicable for operating procedure of Air compressor and Air dryer at {Company Name} {Company Location}.

- RESPONSIBILITY:

- Technical Assistant – Engineering is responsible for operating the equipment as per the SOP.

- HOD/Executive – Engineering is ensure the compliance as per SOP.

- ACCOUNTABILITY:

Engineering Head

Head Quality Assurance

- PROCEDURE:

- Procedure for operating procedure of Air compressor and Air dryer:

- Check the water level in the cooling tower (It should be half of the level).

- Switch “ON” the cooling tower water pump and cooling tower ID fan.

- Check the water pump and ensure inlet pressure should be 2.5 – 3.5 kg/cm².

- Check the oil level in compressor and ensure that 3/4th level of the sight glass.

- Check and ensure the drier inlet valve and compressor discharge valve is open.

- Switch ‘ON’ the control supply of compressor and the message will be display in the MMI Screen as ALL CONDITIONS ARE OK.

- Switch ‘ON’ the air dryer by putting MCB in “ON” position.

- Then start the compressor by pressing the ‘ON’ push button.

- Verification parametersCompressor Oil pressure NLT 0.8 Bar.

- Air compressor element 2 outlet temperature NMT 200°C

- Air compressor Discharge air pressure should be NMT 10 Bar.

- Set the loading and unloading pressure between 7 to 10 Bar.

- Ensure dew point of compressed air in air dryer ≤ -40°C.

- Safety PrecautionDon’t do any maintenance when the compressor is in running condition.

- Stopping Procedure.

- Stop the compressor by pressing the OFF-push button.

- In any emergency cases press emergency button for stopping air compressor

- Switch OFF the air dryer.Stop the cool water pump and cooling tower fan.

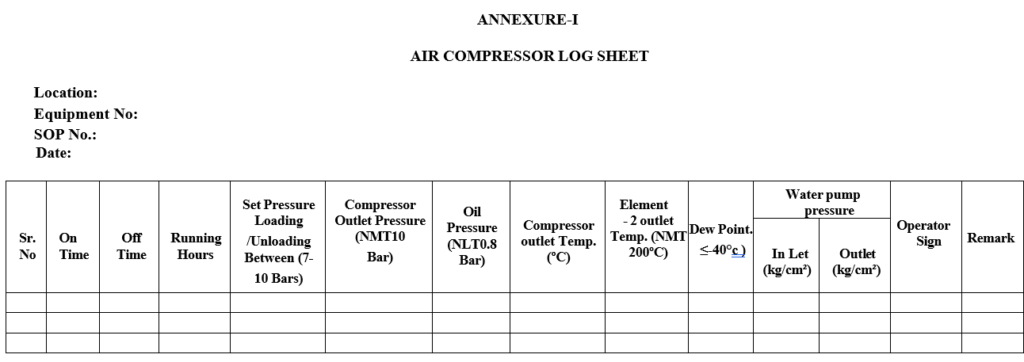

- Every two hours, record the parameters as per Annexure-I.

- REFERENCES:

Not Applicable

- ANNEXURES:

| ANNEXURE No. | TITLE OF ANNEXURE |

| Annexure-I | Air Compressor Log Sheet. |

ENCLOSURES: SOP Training Record.

- DISTRIBUTION:

- Controlled Copy No. 01 Head Quality Assurance

- Controlled Copy No. 02 Head-Engineering

- Master Copy Quality Assurance Department

- ABBREVIATIONS:

Kg/cm² : Kilogram / Square centimeter

MMI : Man Machine Interface

NMT : Not More Than

NLT : Not Less Than

°C : Degree Centigrade

- REVISION HISTORY:

CHANGE HISTORY LOG

| Revision No. | Details of Changes | Reason for Change | Effective Date |

| 00 | New SOP | Not Applicable | To be written manual |

ANNEXURE-I

AIR COMPRESSOR LOG SHEET